The McLease AIRPRO: Industrial Air Compressor & Air Dryer Unit is the critical powerhouse that provides the clean, dry, pressurized "auxiliary air" essential for your advanced metal cutting and automation machinery. This is a complete, integrated system that ensures optimal performance, extends machine life, and guarantees the quality of your cuts and welds.

What it is & How it Works (Engineering Principle):

This unit consists of two primary components:

- Air Compressor: This machine draws in atmospheric air, compresses it to a high pressure (e.g., 7-10 bar), and stores it in a receiver tank. For continuous industrial use, Rotary Screw Compressors are highly recommended due to their efficiency, continuous operation capability, and lower noise levels compared to piston/reciprocating types.

- Air Dryer: Compressed air naturally contains moisture (water vapor). The air dryer removes this moisture. Most commonly, a Refrigerant Dryer cools the air to condense the water out, while for very dry air (required for lasers), a Desiccant Dryer uses absorbent material to remove even more moisture, achieving a very low "dew point." The compressed, dried air is then filtered further (using pre-filters and after-filters) to remove oil and particulates before being delivered to your machinery.

Why is Clean, Dry Air Essential for Your Machines?

- For Fiber Laser Cutters: Auxiliary air (compressed air) is often used as an assist gas for cutting certain materials like mild steel or aluminum. It also purges the cutting head, protecting delicate optics (lenses, nozzles, protective windows) from smoke and debris. Moisture or oil in the air can severely damage laser optics and impair cutting quality.

- For CNC Plasma Cutters: Compressed air is the primary plasma gas for cutting many materials. Moisture in the air leads to poor cut quality, dross, electrode and nozzle degradation, and inconsistent piercing.

- For General Industrial Automation: Clean, dry air is vital for the reliable operation of pneumatic components (cylinders, valves) in your CNC machines and welding automation systems, preventing rust, blockages, and premature wear.

Harmful Effects if Not Bought / Poor Quality Air:

Without a proper Air Compressor & Dryer unit, or with poor quality air:

- Damaged Optics (Lasers): Moisture and oil can condense on expensive laser optics, causing irreparable damage and requiring costly replacement.

- Poor Cut Quality: Leads to dross, rough edges, inconsistent cuts, and reduced accuracy in both laser and plasma cutting.

- Increased Consumable Wear: Reduces the lifespan of laser nozzles, plasma electrodes, and nozzles, increasing operating costs.

- Machine Damage: Moisture causes rust in air lines, pneumatic components, and can even freeze in lines during colder conditions.

- Safety Risks: Contaminated air can pose health risks to operators if exhausted directly.

Key Features (of the Equipment):

- Compressor Type: Rotary Screw (recommended for continuous, stable air supply).

- Flow Rate: Measured in CFM (Cubic Feet per Minute) or LPM (Liters per Minute), indicating how much air the unit can supply.

- Pressure: Output pressure (e.g., 7-10 Bar / 100-145 PSI), essential for cutting processes.

- Motor Power (HP): The compressor's motor horsepower.

- Air Receiver Tank: Volume (Liters) for stable air pressure and storage.

- Dryer Type: Refrigerant (standard industrial dry air) or Desiccant (ultra-dry air for critical laser applications).

- Dew Point: For dryers, indicates the dryness of the air (lower is drier).

- Filters: Integrated pre-filters and after-filters to remove oil, water, and particulates.

Brief Troubleshooting (Air System related):

- Low Pressure/Insuficient Airflow: Check air leaks in lines, compressor motor operation, or filter blockages.

- Moisture in Air Lines: Dryer malfunction, too small a dryer, or excessive condensation in the air receiver (needs draining).

- Excessive Noise: Compressor needs maintenance, unbalanced fan, or motor issues.

Brief Installation & Maintenance Guidelines:

- Installation: Involves connecting power, air outlet lines to your machine, and ensuring proper ventilation for the unit. A level, clean area is required.

- Maintenance: Regular draining of the air receiver tank (to remove condensed water). Periodically replace air filters. For dryers, check refrigerant levels or desiccant material as per manufacturer's guidelines.

Warranties:

All McLease AIRPRO units come with the standard manufacturer's warranty (typically 12-24 months), covering defects in materials and workmanship.

McLease Selling Price Based on Machine Compatibility (Outright Sale - No Leasing):

A. For Fiber Laser Cutters (Requires High Purity, Dry Air)

- For 3kW Fiber Laser (Approx. 10-15 HP Rotary Screw Compressor + Desiccant Dryer or Precision Refrigerant Dryer)

- Recommended Flow: 1000-1500 LPM (35-50 CFM)

- Total McLease Selling Price: INR 6,00,000

- Approximate Price Breakup:

- Compressor Unit: INR 3,80,000

- Desiccant Dryer & Filters: INR 2,20,000

- For 6kW Fiber Laser (Approx. 15-25 HP Rotary Screw Compressor + Desiccant Dryer)

- Recommended Flow: 1500-2500 LPM (50-90 CFM)

- Total McLease Selling Price: INR 8,50,000

- Approximate Price Breakup:

- Compressor Unit: INR 5,50,000

- Desiccant Dryer & Filters: INR 3,00,000

- For 12kW Fiber Laser (Approx. 30-50 HP Rotary Screw Compressor + Desiccant Dryer)

- Recommended Flow: 2500-4000 LPM (90-140 CFM)

- Total McLease Selling Price: INR 12,50,000

- Approximate Price Breakup:

- Compressor Unit: INR 8,00,000

- Desiccant Dryer & Filters: INR 4,50,000

B. For CNC Plasma Cutters (Requires Good Quality, Dry Air)

- For 125A - 200A Plasma Cutter (Approx. 10-20 HP Rotary Screw Compressor + Refrigerant Dryer)

- Recommended Flow: 1000-2000 LPM (35-70 CFM)

- Total McLease Selling Price: INR 4,00,000

- Approximate Price Breakup:

- Compressor Unit: INR 3,40,000

- Refrigerant Dryer & Filters: INR 60,000

- For 200A - 300A Plasma Cutter (Approx. 20-40 HP Rotary Screw Compressor + Refrigerant Dryer)

- Recommended Flow: 2000-4000 LPM (70-140 CFM)

- Total McLease Selling Price: INR 7,00,000

- Approximate Price Breakup:

- Compressor Unit: INR 5,80,000

- Refrigerant Dryer & Filters: INR 1,20,000

(features (e.g., variable speed drive), exact specifications vary prices. Desiccant dryers significantly increase cost compared to refrigerant dryers. GST extra as applicable.)

Product Attributes (for Air Compressor & Dryer Unit Selector):

Customers can use these attributes to find / inform the right unit:

- Machine Compatibility: (e.g., 3kW Fiber Laser, 6kW Fiber Laser, 12kW Fiber Laser, 125A-200A Plasma, 200A-300A Plasma)

- Compressor Type: (e.g., Rotary Screw, Piston/Reciprocating)

- Air Dryer Type: (e.g., Refrigerant Dryer, Desiccant Dryer)

- Flow Rate (CFM/LPM): (e.g., 35-50 CFM, 50-90 CFM, 90-140 CFM+)

- Pressure (Bar): (e.g., 7 Bar, 8 Bar, 10 Bar)

- Horsepower (HP): (e.g., 10 HP, 15 HP, 20 HP, 30 HP, 40 HP)

- Air Receiver Tank Size (Liters): (e.g., 200L, 300L, 500L)

- Dew Point (for Dryer): (e.g., +3°C, -20°C, -40°C)

- Brand Preference: (e.g., Atlas Copco, Kaeser, Ingersoll Rand, Elgi, CompAir, Chicago Pneumatic, Shivam, Fusheng, Technofab)

- Price Range: (e.g., Below 5L, 5L-8L, Above 8L)

Why Buy Your Air Compressor & Dryer Unit Online on www.mclease.com?

Ensure Pristine Air Quality & Peak Machine Performance – Effortlessly!

Clean, dry auxiliary air is the lifeblood of your precision cutting and welding machines. While you could buy directly from a supplier, McLease.com offers a curated selection and unique advantages that ensure you get the perfect air solution for optimal machine health and output.

- Precision Matched to Your Machine: We help you select the AIRPRO unit with the exact flow rate, pressure, and dryness (dew point) required by your Fiber Laser or Plasma Cutter, preventing costly damage to optics and ensuring superior cut quality.

- Curated & Compatible Selection: We've streamlined your choice! Our AIRPRO units are carefully selected from reputable brands, combining robust compressors with efficient dryers, ensuring reliability and compatibility with various industrial applications.

- Competitive Pricing: Access high-quality industrial air systems at excellent prices, ensuring optimal value for your investment.

- Seamless Online Purchase: Easily browse, compare, and order your Air Compressor & Dryer Unit from anywhere, anytime, with our user-friendly online platform.

- Manufacturer's Warranty: All AIRPRO units come with the full manufacturer's warranty, giving you direct assurance from the original maker.

- Expert Guidance (Through Service): While this is an outright sale, our deep understanding of machine requirements ensures you get the right advice on selecting the ideal air solution for your specific laser or plasma system.

- Variety of Payment Modes: Enjoy ultimate flexibility! Pay using Credit/Debit Cards, UPI, Online/Offline Bank Transfers, and even Cash on Delivery (COD) for convenient purchase.

Protect your critical components and guarantee superior cut quality – Invest in McLease AIRPRO today!

Add the McLease AIRPRO to your cart NOW!

McLease Contact:

Website: shop.mclease.com

Phone: +91-9029026000

Email: info@mclease.com

Air Compressor & Dryer - Clean Air for Laser/Plasma | McLease

Shop McLease AIRPRO: Industrial Air Compressor & Air Dryer Unit. Essential for Laser, Plasma, Automation. Ensures clean, dry air & machine protection. Buy online

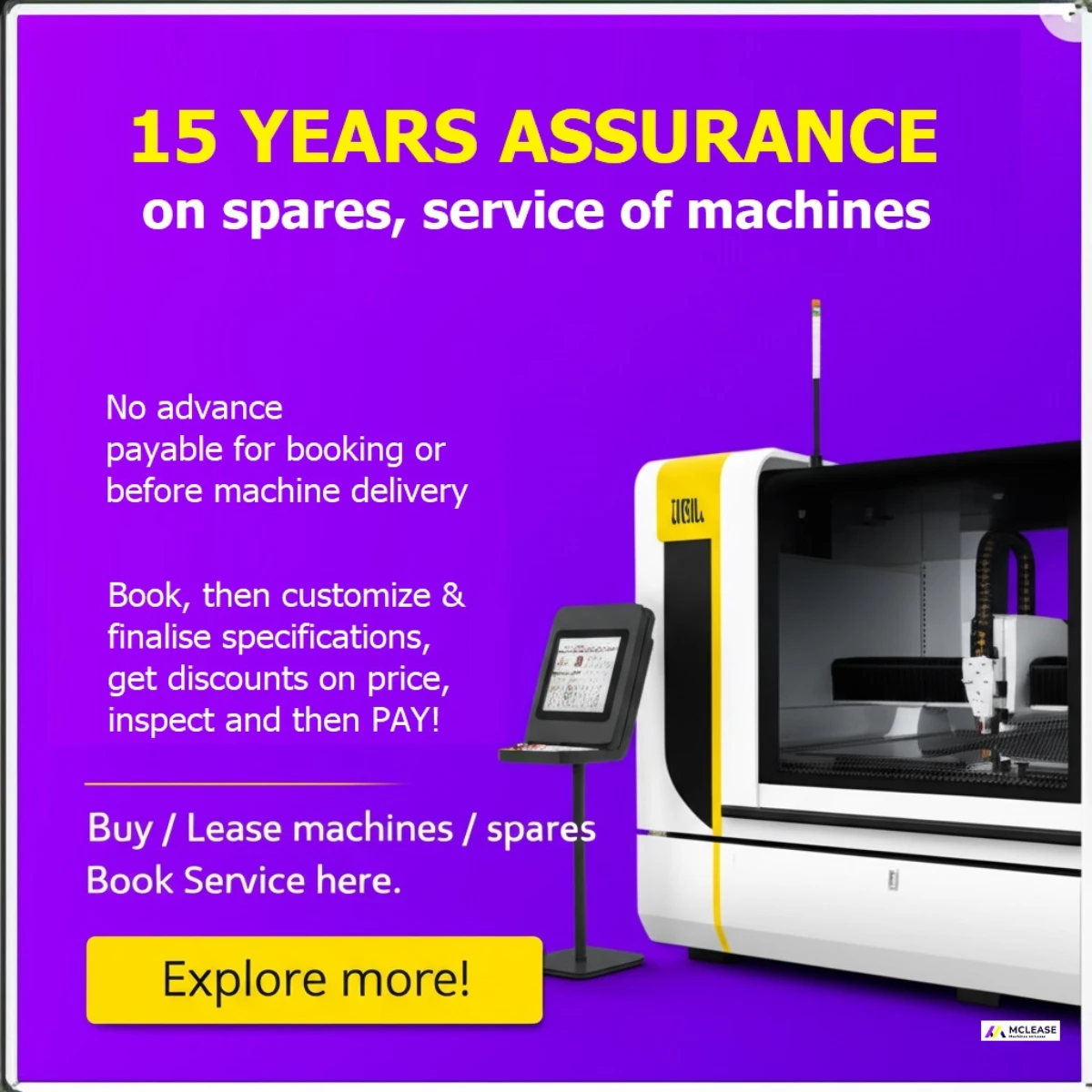

0% Advance, No payment to place order.

0% Advance, No payment to place order.

Safe Payment. Escrow & Routing facility.

Safe Payment. Escrow & Routing facility.

Lease and Buy Back / Sell Back.

Lease and Buy Back / Sell Back.

15 year spares, service ASSURED.

15 year spares, service ASSURED.