The McLease BEAMWELD PRO is a cutting-edge Fiber Laser Welding Machine, proudly manufactured by Technocrats Plasma Systems Ltd., Mumbai, an industry pioneer with over 35 years of expertise. This advanced system redefines precision and efficiency in welding, delivering superior quality welds at high speeds with minimal heat impact. Available in powerful 3kW and 6kW versions, the BEAMWELD PRO offers flexible configurations from manual handheld operation to fully automated solutions, tailored to your production needs.

What it is & Basic Engineering Principle: A Fiber Laser Welding Machine uses a highly focused, high-intensity laser beam to precisely melt and join metal parts. The laser beam is generated by a fiber laser source and delivered to the workpiece via a flexible optical fiber. When this concentrated laser energy hits the material, it creates a deep, narrow "keyhole" of molten metal, allowing for deep penetration welds. This process results in extremely clean, strong, and visually appealing weld seams.

Major Components:

Fiber Laser Source: The heart of the machine, generating the high-power laser beam (e.g., Maxphotonics as standard, IPG as an optional upgrade).

Laser Welding Head: Delivers and focuses the laser beam.

Manual/Handheld: Comes with a compact, ergonomically designed welding gun held and operated manually.

Semi-Automatic: Includes the manual gun, often paired with basic welding jigs/fixtures or simple linear slides for guided, part-specific welding.

Automatic (CNC/Robotic): Features an advanced welding head mounted on a high-precision motion system.

Motion System (for Automatic Versions): This system precisely moves the welding head relative to the workpiece.

How Automatic Motion is Achieved: The welding head is moved by highly precise AC Servo Motors and drives, coupled with precision mechanical components for smooth, repeatable motion.

Types of Automation:

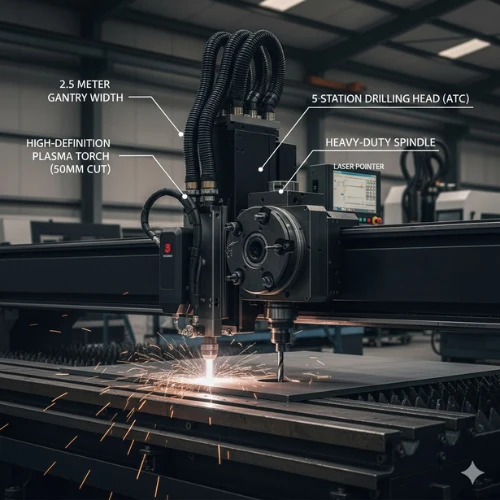

CNC Gantry: For large, flat workpieces or very long linear welds, a gantry system (similar to those on cutting machines, but adapted for welding) precisely moves the welding head across a large working area. It uses linear guides and precision ball screws/rack & pinion systems for accurate positioning. This version does NOT include a cutting table; the workpiece is placed on a welding fixture or support.

Robotic Arm: For complex 3D contours, multi-axis motion, or highly versatile part geometries, a multi-axis industrial robotic arm (e.g., 6-axis articulated robot from brands like FANUC, KUKA, ABB, Yaskawa) precisely manipulates the welding head.

Key Components for Automatic Motion: Robotic arm/CNC gantry structure, AC Servo Motors & Drives, Precision Linear Guides, Ball Screws (for Z-axis and some linear axes), Robotic Manipulators, dedicated Robot Controller / Industrial PC with CNC Controller, and often specialized Vision Systems/Seam Tracking Sensors for higher precision and adaptability.

Cooling System (Chiller): A high-capacity industrial water chiller to maintain the optimal temperature of the laser source and welding head.

Control System: An intelligent CNC/PLC controller with intuitive software for precise programming of welding parameters, path control, and real-time monitoring.

Wire Feeder (Optional): For applications requiring filler material.

Gas Delivery System: For inert shielding gas (e.g., Argon, Nitrogen) to protect the weld pool.

Welding Capabilities (Metals & Thicknesses):

Types of Welding Joints: Fiber laser welding excels at a variety of joints, ensuring deep penetration and clean aesthetics:

Butt Joints, Lap Joints, Fillet Joints, Corner Joints, Edge Welding, Seam Welding.

Welding Angles: Automated (CNC/Robotic) systems provide precise control over welding angles, including:

Work Angle: The angle of the torch relative to the surface of the workpiece.

Travel Angle: The angle of the torch along the direction of travel. This precise control is crucial for consistent weld penetration and bead shape.

Important Clarification: Beveling Fiber Laser Welding Machines DO NOT perform beveling. Beveling is a cutting operation (done by dedicated laser cutters, plasma cutters, or machining) that prepares the edges of metal plates to create a specific joint geometry (e.g., a V-groove). Fiber laser welding requires accurate joint preparation, including precise bevels if the weld design necessitates them.

Beyond Welding: Optional Laser Processing Capabilities

Cutting Capability (Limited):

Important Clarification: A Fiber Laser Welding Machine is primarily designed and optimized for welding, not for high-speed, precise cutting through thick materials. While a fiber laser can technically cut very thin materials (e.g., up to 1-2mm for mild steel or stainless steel, depending on power), the welding head's optics and the machine's motion system are not engineered for efficient, high-quality cutting operations like a dedicated fiber laser cutting machine.

Recommendation: For dedicated metal cutting applications requiring speed and quality, a separate Fiber Laser Cutting Machine is highly recommended. The BEAMWELD PRO is designed to join, not to sever.

Laser Cleaning / Welding Seam Cleaning / Surface Preparation (Optional Add-on):

Yes, this is a highly effective capability! Fiber lasers are excellent for non-contact surface preparation and cleaning.

How it Works: A high-power pulsed fiber laser can precisely ablate (vaporize) contaminants such as rust, paint, oil, grease, oxides, and other surface impurities from metal surfaces without damaging the base material.

Applications: Pre-weld cleaning (rust, scale, oil removal), post-weld seam cleaning (oxides, discoloration), general surface preparation.

Availability Across Versions: This functionality can be integrated into Manual (Handheld), Semi-Automatic, and Automatic (CNC/Robotic) versions of the McLease BEAMWELD PRO, often requiring a specific laser cleaning scan head or specialized optics and software modules (optional upgrade).

Advantages of Fiber Laser Welding (vs. other welding technologies like MIG/TIG/SAW):

High Speed: Significantly faster welding speeds, boosting productivity.

Low Heat Input & Minimal Distortion: Concentrated energy means less heat spread, reducing material distortion, warping, and the need for post-weld straightening.

Narrow, Deep Welds: Achieves very narrow weld beads with high depth-to-width ratios, leading to strong, efficient joints.

Non-Contact Process: No physical contact between the tool and workpiece, reducing wear and contamination.

Superior Quality & Consistency: Highly repeatable, producing clean, strong, and visually appealing welds with excellent metallurgical properties.

Versatile Automation: Easily integrated with robotics and CNC motion systems.

No Consumable Electrodes/Filler (Autogenous): Often welds without filler material for thin sections, reducing consumable costs.

Disadvantages (vs. other methods):

High Initial Fixed Cost: Higher investment compared to conventional MIG/TIG.

Joint Fit-Up Criticality: Requires very precise joint preparation and tight fit-up for optimal results.

Beam Delivery Limitations: Requires line-of-sight access to the joint.

Safety: Requires strict laser safety protocols.

Cost Comparison (Fixed Cost vs. Operating Cost):

Fixed Cost: Fiber Laser Welding has a higher initial fixed cost (machine purchase) compared to traditional MIG/TIG welding machines.

Operating Cost: However, it often has lower operating costs per meter of weld, especially for higher volume production, due to:

Higher welding speeds (less labor time per part).

Lower consumable cost (less wire, no electrodes for autogenous welds).

Reduced rework/post-processing (due to minimal distortion and high quality).

Lower power consumption compared to some arc welding processes per unit of deposited material.

Basic Troubleshooting Guide:

Poor Weld Quality (Irregular bead, porosity): Check shielding gas flow/purity, laser power/speed settings, joint fit-up, or ensure laser head optics are clean.

No Laser Output: Verify emergency stop is disengaged, check safety interlocks, power source status, and optical fiber connection.

Machine Movement Errors (for Auto versions): Refer to CNC controller troubleshooting guide for motion-related issues.

Installation-Operation-Maintenance:

Installation (Manual): Simple plug-and-play setup for power, gas, and chiller connections.

Installation (Automated): Requires professional installation. Involves positioning the machine/robot, connecting power, industrial gases, and chiller, and setting up optical alignment.

Operation: Program weld parameters via HMI/CNC. Load workpiece. Start weld program. Manual versions require skilled operator handling; automated versions require programming and monitoring.

Maintenance: Regular cleaning of protective optics (cover slide) is critical. Periodically check laser head optics and power source cooling. Ensure high purity of shielding gases. Follow OEM manual for routine checks.

Do's & Don'ts:

DO: Always use proper laser safety eyewear. Ensure precise joint fit-up. Maintain clean optics. Use high-purity shielding gases. Follow all safety protocols.

DON'T: Operate without safety interlocks. Look directly into the laser beam. Weld dirty or improperly prepared surfaces. Never bypass safety features.

A. McLease BEAMWELD HANDY (Manual/Handheld Fiber Laser Welding Machine)

3kW Version:

Monthly Lease Amount (Ex-GST): INR 74,670/-

(Order Booking Security Deposit: 10% of monthly lease = INR 7,467/- - 100% Refundable)

6kW Version:

Monthly Lease Amount (Ex-GST): INR 125,585/-

(Order Booking Security Deposit: 10% of monthly lease = INR 12,558/- - 100% Refundable)

B. McLease BEAMWELD SEMI-AUTO (Semi-Automatic Fiber Laser Welding Machine)

3kW Version:

Monthly Lease Amount (Ex-GST): INR 87,391/-

(Order Booking Security Deposit: 10% of monthly lease = INR 8,739/- - 100% Refundable)

6kW Version:

Monthly Lease Amount (Ex-GST): INR 138,349/-

(Order Booking Security Deposit: 10% of monthly lease = INR 13,835/- - 100% Refundable)

C. McLease BEAMWELD AUTO (Fully Automatic Fiber Laser Welding Machine - CNC/Robotic)

3kW Version:

Monthly Lease Amount (Ex-GST): INR 229,007/-

(Order Booking Security Deposit: 10% of monthly lease = INR 22,901/- - 100% Refundable)

6kW Version:

Monthly Lease Amount (Ex-GST): INR 381,804/-

(Order Booking Security Deposit: 10% of monthly lease = INR 38,180/- - 100% Refundable)

Achieve Perfect Welds, Faster & Smarter – With Unmatched Support!

Acquiring an advanced Fiber Laser Welding Machine like the BEAMWELD PRO is a strategic investment. While you could buy directly from the manufacturer, McLease.com offers an unparalleled ecosystem of benefits that no individual manufacturer or supplier can match. We ensure your purchase is not only technologically superior but also financially savvy and comprehensively supported throughout its entire lifecycle.

Manufactured by Technocrats Plasma Systems Ltd., Mumbai: Benefit from over 35 years of engineering excellence from a trusted Indian manufacturer, ensuring robust and reliable machinery.

Zero Payment to Book! (Only 10% Refundable Security Deposit): Secure your BEAMWELD PRO today for just 10% of the calculated monthly lease amount as a one-time order booking security deposit. This nominal amount confirms your serious intent, allowing us to prioritize your order. This deposit is 100% refundable if leasing documentation is not finalized, or if your order is cancelled by McLease. It's truly a risk-free commitment to explore.

Unmatched 15-Year Service & Spares Assurance: Beyond standard manufacturer warranties, McLease guarantees service and genuine spare parts availability for an incredible 15 years! This commitment ensures your machine performs reliably for its entire extended lifespan, minimizing unexpected costs and maximizing uptime.

Flexible Finance & Easy Leasing with Buyback: Don't tie up your valuable capital! Opt for our flexible leasing options tailored to your business needs, often without rigid CIBIL checks. Our models include buy-back or sell-back options at the end of the lease, giving you ultimate flexibility to upgrade or return.

IPG Laser Sources: Available as a separate lease option from McLease, providing flexibility if you prefer this premium laser source.

AI-Powered Remote Support (RAMC) & AMC: Minimize costly downtime! Your machine comes with access to McLease's innovative Remote Annual Maintenance Contracts (RAMC) for AI-driven preventive maintenance insights and expert remote troubleshooting, often resolving issues without a physical visit.

Productivity Loss Insurance: Gain added peace of mind with insurance coverage against productivity loss due to machine breakdowns.

Seamless Online Support Hub: Manage everything from your computer or mobile! Easily purchase all genuine spares, consumables (like welding wire, shielding gas), and accessories directly from McLease.com. Raise service requests, track engineer movement, and manage your machine's lifecycle digitally.

Variety of Payment Modes: Enjoy ultimate flexibility! Pay your initial security deposit and subsequent monthly lease amounts using Pay Later schemes, Credit/Debit Cards, UPI, Online/Offline Bank Transfers, and even Cash on Dispatch (COD) for the machine itself (terms apply).

Complete Ecosystem Advantage: By choosing McLease, you gain access to a holistic ecosystem that supports not just this machine, but potentially your entire fabrication operation, offering comprehensive financing, maintenance, and supply chain solutions.

Experience the precision and power of the McLease BEAMWELD PRO firsthand. We invite you to book a FREE live demonstration at our facility in Mumbai. See how our Fiber Laser Welding Machine can transform your production quality and speed.

For customers outside Mumbai, our flexible leasing options make it incredibly easy to get started. Leasing is the ideal way to acquire this advanced technology without a large upfront investment.

Contact McLease.com today to book your demo or discuss your requirements!

Prices: All prices are Ex-Works Vasai, Mumbai, India. Prices are indicative estimates and subject to change based on final technical specifications and market conditions.

Additional Charges:

GST: Goods and Services Tax will be extra, as applicable, on all machine values, payments, and services.

Freight: Transportation charges will be at actuals and "To Pay" (customer pays directly at delivery).

Packaging, Forwarding, Insurance (PFI): A charge of 2% of the machine value will be extra.

Installation & Commissioning: Included in the price.

Order Confirmation Deposit: A one-time refundable security deposit of 10% of the calculated monthly lease amount is required at the time of online order booking.

Refund Policy: This deposit is 100% refundable if the leasing documentation is not finalized/proceeded, or if the order is cancelled by McLease for any reason. For other cancellation reasons, standard website cancellation policies (

Leasing Approval: Finalization of lease is subject to McLease's credit assessment (based on repayment capacity/order book) and execution of a formal Lease Agreement.

Service & Spares Assurance: The 15-year assurance is provided by McLease as per the terms and conditions of a separate Service Assurance Agreement and/or AMC/RAMC contracts.

Warranty: The machine comes with a manufacturer's standard warranty (typically 12-18 months), with McLease facilitating claims.

Machine Ownership (Lease): Legal title remains with McLease's financier or McLease until buy-back is exercised.

Governing Law: This proposal and any resulting agreements shall be governed by the laws of India. Courts in Mumbai shall have exclusive jurisdiction.

McLease Contact: Website: shop.mclease.com Phone: +91-9029026000 Email: info@mclease.com

No review given yet!

0% Advance, No payment to place order.

0% Advance, No payment to place order.

Safe Payment. Escrow & Routing facility.

Safe Payment. Escrow & Routing facility.

Lease and Buy Back / Sell Back.

Lease and Buy Back / Sell Back.

15 year spares, service ASSURED.

15 year spares, service ASSURED.