Techno-Commercial Proposal

McLease ORBITWELD PRO: Advanced Orbital Welding System Manufactured in India under Global Technical Collaboration

Prepared for: [Client Company Name] Date: June 22, 2025 Prepared by: McLease

Executive Summary

McLease is proud to introduce the ORBITWELD PRO, a state-of-the-art Orbital Welding System, setting new benchmarks for precision, efficiency, and quality in critical welding applications. Manufactured in India under a strategic technical collaboration with leading global expertise, the ORBITWELD PRO ensures consistent, high-integrity welds that meet the most stringent industry standards.

This proposal details a comprehensive solution, from the advanced power source and intelligent controls to the versatile welding heads. Beyond the superior technology, McLease offers an unparalleled ecosystem of benefits: flexible financing solutions (including lease and buy-back models without CIBIL checks), an industry-leading 15-year service and spares assurance, AI-powered remote maintenance (RAMC), and seamless online support. This guarantees not only the acquisition of a world-class machine but also sustained operational excellence and peace of mind. Invest in the future of precision welding with McLease ORBITWELD PRO.

1. Introduction to Orbital Welding

Orbital welding is a specialized Gas Tungsten Arc Welding (GTAW or TIG) process where the arc rotates mechanically 360 degrees around a static workpiece (typically a pipe or tube). It is the pinnacle of automated welding, designed to produce highly consistent, repeatable, and high-quality welds in applications demanding the utmost precision and integrity. Unlike manual welding, orbital welding eliminates human variability, leading to superior metallurgical properties and flawless aesthetics.

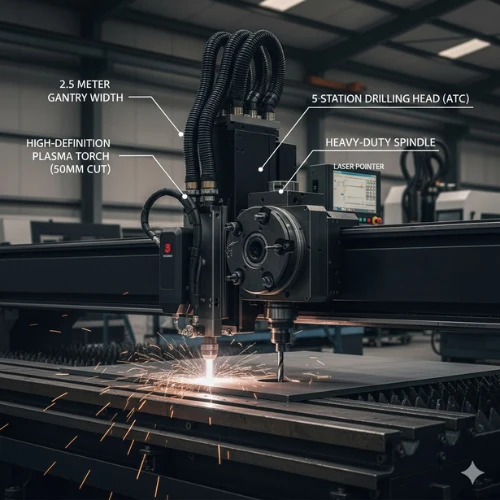

2. McLease ORBITWELD PRO: The Precision Welding Solution

The McLease ORBITWELD PRO is our private label Orbital Welding Machine, combining robust Indian manufacturing capabilities with cutting-edge global technical collaboration. It is engineered for unparalleled performance, offering a comprehensive solution for critical and high-purity welding needs.

2.1. Key Features:

- Advanced Power Source:

- Type: High-frequency inverter-based DC Pulse TIG (GTAW) power source.

- Technology: Latest IGBT technology for stable current control, precise arc initiation, and excellent arc stability.

- Output: Wide current range (e.g., 2-250 Amperes) for various wall thicknesses.

- Intelligent Control System:

- System: Microprocessor-controlled CNC system with real-time process monitoring.

- Interface: Intuitive multi-language touchscreen HMI (Human-Machine Interface).

- Programming: Stores hundreds of weld programs with precise control over current, pulse frequency, travel speed, gas flow, and arc voltage.

- Versatile Welding Heads:

- Closed Orbital Weld Heads: Fully enclosed chambers for high-purity applications, ideal for tube-to-tube and tube-to-fitting welds. Available in various sizes (e.g., for 1/8" to 4" (3mm to 114mm) Outer Diameter pipes/tubes).

- Open Orbital Weld Heads: For larger diameters or specific joint types (e.g., pipe-to-flange, pipe-to-valve). Adaptable for diameters up to 60 inches (1500mm+) with track systems.

- Interchangeability: Quick-change head design for seamless transition between different pipe sizes and applications.

- Integrated Cooling System: High-capacity, integrated water chiller unit specifically designed to cool the welding torch and power source components, ensuring continuous operation and extended consumable life.

- Precise Gas Management: Digital control over pre-purge, weld purge, and post-purge gas flow (e.g., Argon) for optimal shielding and minimal oxidation, crucial for high-integrity welds.

- Wire Feed System (Optional): Integrated cold wire feed unit for applications requiring filler material.

2.2. Advantages & Benefits:

- Unrivaled Quality & Repeatability: Achieves consistent, defect-free welds with superior penetration, bead profile, and metallurgical properties, eliminating human error.

- Enhanced Productivity: Significantly increases welding speed compared to manual methods, reducing project timelines and increasing throughput.

- Cost Efficiency: Minimizes rework, reduces consumable waste, and optimizes labor utilization (less reliance on highly skilled manual welders for consistent results).

- Code Compliance: Produces welds consistently meeting stringent industry codes (e.g., ASME, API, AWS) and quality standards (e.g., ASTM, ISO).

- Improved Safety: Remote operation reduces operator exposure to arc flash, fumes, and heat, enhancing workplace safety.

- Material Versatility: Capable of welding a wide range of materials including Stainless Steel, Titanium, Inconel, Hastelloy, Duplex/Super Duplex steels, etc.

- Auditability: Weld data logging capabilities for process validation and quality assurance.

2.3. Uses / Applications:

The McLease ORBITWELD PRO is essential for industries where weld quality, consistency, and traceability are non-negotiable:

- Pharmaceuticals & Biotech: High-purity piping, sanitary tubing.

- Aerospace: Aircraft hydraulic and fuel lines, structural components.

- Food & Beverage: Sanitary process piping, brewery lines.

- Semiconductor: Ultra-high purity (UHP) gas lines.

- Oil & Gas / Power Generation: Process piping, heat exchangers, boiler tubes.

- Automotive: Exhaust systems, specialized fluid lines.

- Chemical Processing: Corrosion-resistant piping.

2.4. Technical Specifications (Typical Configuration - 150A Power Source, Closed Head System):

| Parameter | Specification |

|---|

| Welding Process | DC Pulse TIG (GTAW) |

| Power Source Output | 2-150 Amperes (Max 250A optional) |

| Rated Output Power | 10-15 kW (Approx.) |

| Input Power | 3-Phase, 415V AC, 50/60Hz |

| Welding Head Types | Closed Orbital Weld Heads, Open Orbital Weld Heads (with Guide Rings/Tracks) |

| Pipe/Tube OD Range (Closed Head) | 1/8" to 4" (3mm - 114mm) standard (various head sizes) |

| Pipe/Tube OD Range (Open Head) | 1" to 60"+ (25mm - 1500mm+) with track and guide band system |

| Wall Thickness | 0.5 mm to 10 mm (single pass), thicker with multiple passes/filler wire |

| Control System | Microprocessor-controlled, Touchscreen HMI, Multi-program Memory |

| Arc Voltage Control (AVC) | Integrated for precise arc gap maintenance |

| Oscillation (Wobble) | Programmable (for wider welds, especially with open heads) |

| Wire Feed Speed | Programmable (0-5 m/min typical for cold wire, if optional) |

| Shielding Gas | Argon (99.999% purity recommended) |

| Cooling | Integrated Water Chiller (closed-loop) |

| Dimensions/Weight | Varies by model (Power source ~50-100 kg, heads ~2-15 kg) |

2.5. Recommended Components / Brands (Readily Available in India):

As a McLease private label product manufactured in India under technical collaboration, our ORBITWELD PRO integrates components from renowned and reliable suppliers, ensuring quality and competitive pricing.

- Power Electronics (IGBT Modules, Digital Controls): Infineon, Fuji Electric, Semikron (core technology components).

- Control System (PLC/HMI): Siemens, Schneider Electric, Delta, Panasonic (for robust and programmable control logic).

- Servo/Stepper Motors & Drives (for Head Movement): Panasonic, Yaskawa, Delta, Leadshine (for precise rotation and wire feed).

- Cooling System (Chiller): Gem Orion, S&A, Hexacool (Indian and global brands known for industrial chillers).

- Pneumatics (for clamping/purging): Festo, SMC, Janatics (for reliable gas and clamping control).

- Sensors & Relays: Omron, Teknic, Phoenix Contact (for robust electrical control and feedback).

- Cables & Connectors: LAPP, Polycab, Finolex (for high-quality power and signal transmission).

- HMI/Touchscreen: Weintek, Delta (user interface for programming and monitoring).

- Proprietary Welding Head Mechanics: Designed in collaboration with global partners, manufactured to high precision standards in India.

2.6. Limitations:

- Initial Investment: Higher upfront cost compared to manual welding equipment.

- Joint Preparation: Requires precise joint preparation and fit-up for optimal results.

- Geometric Constraints: Best suited for pipe/tube-to-pipe/tube, pipe-to-fitting, or specific tube-sheet joints. Not ideal for highly irregular or complex geometries.

- Operator Training: While automated, requires skilled operators for programming, setup, and troubleshooting.

- Consumables: High purity shielding gas and electrodes are essential.

3. Why Choose McLease for Your ORBITWELD PRO?

Choosing McLease for your Orbital Welding Machine is a strategic decision that goes beyond acquiring world-class technology. We empower your business with an unparalleled ecosystem of financial flexibility, long-term support, and seamless digital integration that no manufacturer alone can provide:

- Zero Upfront Payment: Book your ORBITWELD PRO today with no advance payment required until machine delivery, significantly easing your initial capital outlay.

- 15-Year Service & Spares Assurance: Experience unmatched peace of mind. As a McLease private label, we guarantee service and genuine spare parts availability for 15 years, ensuring continuous operation.

- Flexible Finance, No CIBIL Check: Acquire this advanced machine without rigid bank loan requirements. Our tailored leasing solutions are based on your business's true repayment capacity and order book, not just CIBIL scores.

- AI-Powered Remote Support (RAMC): Maximize machine uptime with our innovative Remote Annual Maintenance Contracts. Benefit from AI-based preventive maintenance insights and expert remote troubleshooting, often resolving issues without a site visit.

- Seamless Online Support Hub: Effortlessly manage your machine! Easily purchase all genuine spares, consumables, and accessories directly from McLease.com. Raise service requests, track engineer movement, and utilize various payment modes, including "Pay Later."

- Manufactured with Global Collaboration: The ORBITWELD PRO combines robust Indian manufacturing with cutting-edge global technical expertise, delivering a high-quality, reliable machine at a competitive value.

- Complete Ecosystem Advantage: McLease offers a holistic solution – from flexible financing and advanced technology to unmatched long-term service and digital support – an integrated value proposition unavailable from direct manufacturer purchases.

4. Commercial Aspects & Financial Solutions

The indicative cost of a standard ORBITWELD PRO system starts from around INR 25 - 40 Lakhs depending on features/kW. Final pricing will depend on the specific configuration (e.g., head types, power source capacity, optional features).

McLease offers comprehensive acquisition models tailored to your financial strategy:

- Outright Purchase: Competitive pricing for direct acquisition.

- Flexible Leasing Options: Tailored lease agreements designed to optimize your capital expenditure and cash flow, potentially structured around your work order potential.

- Buy Back / Sell Back Options: Clauses allowing for future buy-back or sell-back arrangements at the end of the lease period.

- Innovative Financing: Beyond leasing, we can facilitate unique financing solutions that do not require CIBIL/CMR checks, including potential raw material financing.

5. Call to Action

Don't compromise on weld quality, productivity, or financial flexibility!

Contact McLease today to discuss your specific requirements and receive a customized proposal for your ORBITWELD PRO Orbital Welding System.

Revolutionize your welding operations with McLease – where precision engineering meets unmatched support and flexible finance.

0% Advance, No payment to place order.

0% Advance, No payment to place order.

Safe Payment. Escrow & Routing facility.

Safe Payment. Escrow & Routing facility.

Lease and Buy Back / Sell Back.

Lease and Buy Back / Sell Back.

15 year spares, service ASSURED.

15 year spares, service ASSURED.