Techno-Commercial Proposal

McLease H-BEAM MASTER PRO: Integrated H-Beam Production Line (Assembly, MIG Welding, Tandem SAW Welding, CNC Drilling, CNC Plasma-OxyFuel & Straightening)

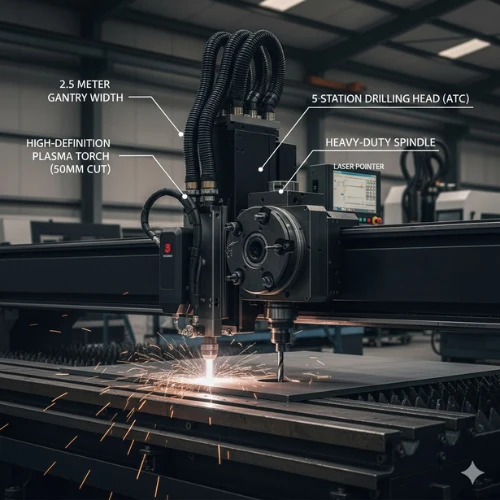

Revolutionizing Heavy Fabrication with a Multi-Functional Gantry

Prepared for: Valued Client

Date: July 2, 2025

Prepared by: McLease (Vula Technologies Private Limited)

Website: www.mclease.com

Executive Summary

McLease is proud to present the H-BEAM MASTER PRO, a revolutionary, integrated H-Beam Production Line designed for unparalleled efficiency, precision, and automation in heavy structural steel fabrication. This system uniquely leverages a single, robust, multi-functional gantry to precisely integrate H-Beam assembly, MIG tack welding, high-speed Tandem Submerged Arc Welding (SAW), CNC drilling, and CNC Plasma-OxyFuel cutting, delivering a highly cost-effective and streamlined solution for manufacturing H/T beams up to 12 x 6 meters.

This proposal details the cutting-edge technology behind this integrated system, emphasizing the significant advantages of its shared gantry platform. Beyond superior engineering, McLease offers an unparalleled ecosystem of benefits: flexible financing solutions (including lease with buyback, zero advance options), an industry-leading 15-year service and spares assurance, AI-powered remote maintenance (RAMC), and seamless online support, and optional bundling of essential ancillary systems like Fume Extractors and Power Conditioners. Invest in enhanced productivity, unwavering reliability, and financial peace of mind with McLease H-BEAM MASTER PRO.

1. The Power of Tandem SAW: High Productivity & Quality

Submerged Arc Welding (SAW) is a highly efficient welding process, particularly suited for thick materials and long, continuous welds. Tandem SAW takes this a step further by using two independent welding wires (lead and trail) fed into a single molten pool, significantly increasing welding speed and deposition rates. This means fewer passes, faster completion times, and superior weld quality compared to single-wire SAW or other processes.

1.1. Common Materials & Thickness Range in India:

This integrated system excels in heavy fabrication for the same materials suited for Tandem SAW:

- Mild Steel & Low Alloy Steels (e.g., IS 2062 Grade B, ASTM A36): Typically 8 mm to 100 mm and above.

- Boiler Quality Plates (e.g., IS 2002, SA 516 Gr. 70): 10 mm to 150 mm and beyond.

- High Strength Low Alloy (HSLA) Steels: 8 mm to 50 mm.

2. McLease H-BEAM MASTER PRO: Machine Specifications

The H-BEAM MASTER PRO is configured for high-performance and reliable operation, designed for H/T beams up to 12 meters long with a 6-meter width access, all within a unified system.

2.1. Core Integrated System Components (Leveraging Shared Gantry):

- Multi-Functional Gantry Structure:

- Description: A single, robust, heavy-duty gantry, precision-engineered to act as the universal motion backbone for multiple processes.

- Working Area: Designed to cover workpieces up to 12 meters (length) x 6 meters (width).

- Movement: Motorized longitudinal travel along ground rails (for 12m length), motorized cross-travel of the trolley along the gantry bridge (for 6m width), and motorized vertical lift/lower of the various process heads.

- Structure Material: Heavy-duty fabricated steel sections, precision machined.

- Precision Motion Components: Utilizes high-performance AC Servo motors, high-accuracy linear guide rails, and precision gear racks & pinions for smooth, precise, and powerful movement across all axes.

- Integrated H-Beam Assembly & MIG Welding (Tack Welding) Heads:

- Function: Mounted on the shared gantry, these heads perform the precise alignment and synchronized hydraulic clamping of the web and flange plates.

- Welding Process: MIG tack welding with programmable time-based weld/skip settings for initial joint integrity.

- Integrated Tandem SAW Welding System (The Powerhouse Welder):

- Function: Mounted on the same multi-functional gantry, this is a 1200 Amps Tandem SAW system (two independent welding wires: Lead DC, Trail AC) that performs the main, high-deposition fillet welds joining the web to the flanges.

- Flux Management: Includes a large capacity heated flux hopper, automatic feeding, and integrated vacuum-type flux recovery.

- Key Features: Automatic Arc Voltage Control (AVC), motorized cross slide for precise torch positioning, and capability for high welding speeds (e.g., 20-150 cm/min).

- [Optional] Integrated CNC Drilling Head:

- Function: A drilling spindle can be mounted on the same gantry, allowing automated hole drilling on the H-beams.

- [Optional] Integrated CNC Plasma-OxyFuel Cutting Machine:

- Function: For ultimate versatility, a Plasma and/or Oxy-Fuel torch cutting station can be integrated onto the gantry, allowing precise profile cutting of plates (for flanges/webs or other parts) before or after H-beam assembly, all on the same system.

- Intelligent Control System:

- System: A single, central CNC/PLC control panel with an intuitive HMI manages and synchronizes all integrated processes (gantry movement, assembly clamping, tack welding, Tandem SAW parameters, CNC drilling, Plasma-OxyFuel cutting, etc.).

- Parameter Storage: Ability to store and recall comprehensive production and welding programs.

2.2. Standalone Hydraulic Flange Straightening Machine (Post-Process):

- Important Note: The final Hydraulic Flange Straightening Machine is typically a separate, standalone unit. This is due to the immense forces required to correct heat-induced deformation in welded H-beam flanges.

- Operation: A powerful hydraulic machine with hardened alloy steel straightening wheels and drive rollers precisely restores flange linearity. The welded H-beam is transferred from the gantry's working area to this machine for the final straightening step.

2.3. Welding Quality Standards (Common in India):

The system is designed to help you achieve welds compliant with: IS 4353, AWS D1.1/D1.1M, ASME Boiler and Pressure Vessel Code (Section IX), and NABL Accreditation for testing.

2.4. Typical Welding Speed:

With the 1200 Ampere tandem SAW system integrated, welding speeds for H-beam seams vary:

- For thinner sections (e.g., 8-15mm): 80-150 cm/min.

- For medium sections (e.g., 16-40mm): 40-80 cm/min.

- For thick sections (e.g., 40-100mm+): 20-50 cm/min per pass.

3. Operational Advantages & Benefits

The McLease H-BEAM MASTER PRO offers profound operational advantages:

- Reduced Capital Investment: Avoids the significant cost of separate gantries and control systems for each process.

- Optimized Factory Footprint: Consolidates multiple processes onto one platform, saving valuable floor space.

- Streamlined Production Workflow: Minimizes material handling between assembly, tack welding, main SAW welding, drilling, and cutting by performing these sequential operations under a single gantry.

- Faster Throughput: Seamless transition between processes and high SAW speeds lead to higher overall production.

- Superior Quality & Accuracy: A single, highly precise gantry ensures consistent alignment and geometric accuracy throughout the entire beam fabrication.

- Cost Efficiency: Optimizes consumables, reduces rework, and lowers labor costs.

- Enhanced Safety: Automated operations reduce operator exposure to hazards.

4. Why Buy Your H-BEAM MASTER PRO Online on www.mclease.com?

Power Your Fabrication with Precision & Unmatched Support – Effortlessly!

Acquiring an integrated H-Beam production system is a monumental investment. While you could buy directly from a manufacturer, McLease.com offers an unparalleled ecosystem of benefits that no individual manufacturer or supplier can match. We ensure your investment is not only technologically superior but also financially savvy and comprehensively supported throughout its entire lifecycle.

- Zero Payment to Book! (Only 1% Refundable Security Deposit): Secure your H-BEAM MASTER PRO today for just 1% of the calculated monthly lease amount as a one-time order booking security deposit. This nominal amount confirms your serious intent, allowing us to prioritize your order. This deposit is 100% refundable if leasing documentation is not finalized, or if your order is cancelled by McLease. It's truly a risk-free commitment to explore.

- Unmatched 15-Year Service & Spares Assurance: Beyond standard manufacturer warranties, McLease guarantees service and genuine spare parts availability for an incredible 15 years! This commitment ensures your machine performs reliably for its entire extended lifespan, minimizing unexpected costs and maximizing uptime.

- Flexible Finance & Easy Leasing with Buyback: Don't tie up your valuable capital! Opt for our flexible leasing options tailored to your business needs, often without rigid CIBIL checks. Our models include buy-back or sell-back options at the end of the lease, giving you ultimate flexibility to upgrade or return. Lease arrangements are preferred if a minimum of 2 machines are simultaneously purchased.

- AI-Powered Remote Support (RAMC) & AMC: Minimize costly downtime! Your machine comes with access to McLease's innovative Remote Annual Maintenance Contracts (RAMC) for AI-driven preventive maintenance insights and expert remote troubleshooting. Comprehensive AMC options are also available.

- Productivity Loss Insurance: Gain added peace of mind with insurance coverage against productivity loss due to machine breakdowns.

- Seamless Online Support Hub: Manage everything from your computer or mobile! Easily purchase all genuine spares, consumables (like welding wire, flux), and accessories directly from McLease.com. Raise service requests, track engineer movement, and manage your machine's lifecycle digitally.

- Variety of Payment Modes: Enjoy ultimate flexibility! Pay your initial security deposit and subsequent monthly lease amounts using Pay Later schemes, Credit/Debit Cards, UPI, Online/Offline Bank Transfers, and even Cash on Dispatch (COD) for the machine itself (terms apply).

- Complete Ecosystem Advantage: By choosing McLease, you gain access to a holistic ecosystem that supports not just this machine, but potentially your entire fabrication operation, offering comprehensive financing, maintenance, and supply chain solutions.

- Optional Bundling of Essential Accessories: For complete peace of mind and simplified procurement, you can bundle essential ancillary systems like Fume Extraction Systems/Dust Collectors and Power Conditioning Units (Online UPS / Voltage Stabilizer / Isolation Transformer) directly with your machine order, ensuring optimal machine health and operator safety from day one.

5. Commercial Proposal & Pricing

All prices are indicative and subject to final configuration, prevailing market conditions, and GST (Goods and Services Tax) as applicable.

5.1. Core Components / Systems (McLease Selling Price - for reference):

- Core Tandem SAW Power Source & Welding Head (Standalone):

- McLease Selling Price: INR 90,00,000 (90 Lakhs) (approx. USD 108,000)

- Heavy-Duty Column & Boom Manipulator (Standalone):

- McLease Selling Price: INR 1,38,00,000 (1.38 Crore) (approx. USD 165,000)

- Heavy-Duty Gantry Welding System (Standalone Gantry Structure & Motion, without welding head/power source):

- McLease Selling Price: INR 3,18,00,000 (3.18 Crore) (approx. USD 382,000)

- Standalone Hydraulic Flange Straightening Machine:

- McLease Selling Price: INR 80,00,000 (80 Lakhs) (approx. USD 96,000)

0% Advance, No payment to place order.

0% Advance, No payment to place order.

Safe Payment. Escrow & Routing facility.

Safe Payment. Escrow & Routing facility.

Lease and Buy Back / Sell Back.

Lease and Buy Back / Sell Back.

15 year spares, service ASSURED.

15 year spares, service ASSURED.