The McLease FIBERHEAD PRO is a complete, advanced Laser Cutting Head Assembly, crucial for high-performance Fiber Laser Cutting Machines. It precisely focuses the powerful laser beam onto the metal surface, enabling clean, fast, and accurate cuts across a wide range of material thicknesses. This is not just a bare head unit, but a fully assembled system including all necessary optical components, focusing mechanisms, and connections, ready for seamless integration. Available for various power levels including 3kW, 6kW, 12kW, and higher.

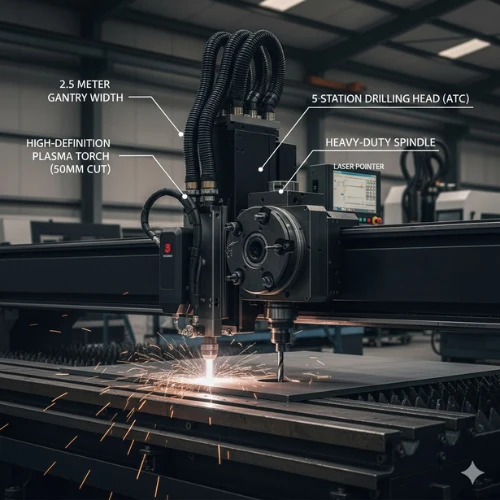

What it is & How it Works (Engineering Principle):

The laser cutting head acts as the "business end" of your fiber laser system. It receives the high-power laser beam from the laser source via a fiber optic cable. Inside, a series of precision lenses collimate (make parallel) and then precisely focus this beam into an incredibly tiny, high-energy spot on the metal workpiece. Simultaneously, an assist gas (like oxygen or nitrogen) is delivered through a nozzle to clear molten material and prevent oxidation, completing the cutting process.

Use & Application:

The FIBERHEAD PRO is indispensable in Fiber Laser Cutting Machines for cutting various metals including mild steel, stainless steel, aluminum, brass, and copper. It's a core component for industries such as metal fabrication, automotive, construction, general engineering, and any sector demanding precise metal profiling and processing.

Operation:

The laser cutting head operates in conjunction with the machine's CNC (Computer Numerical Control) system. The CNC dictates the cutting path and accurately controls the head's Z-axis movement and sophisticated auto-focusing mechanism to maintain the optimal focal distance from the workpiece surface, ensuring consistent cut quality.

Key Features for Superior Performance (Scalable to all Power Levels):

- Advanced Auto-Focusing Capability: This is a crucial feature that automatically adjusts the focal length in real-time. It's vital for achieving consistent cut quality across varying material thicknesses, managing surface irregularities, and optimizing piercing/cutting without manual intervention.

- Robust Cooling System: Integrated internal cooling systems (typically closed-loop water-cooled) efficiently dissipate the significant heat generated during high-power laser operation. This protects sensitive optical components, extends their lifespan, and ensures stable cutting performance even during long production runs.

- Anti-Collision Protection: Incorporated sensors and safety mechanisms protect the cutting head from costly damage in case of accidental contact with the workpiece, clamps, or fixturing. This minimizes repair expenses and crucial production downtime.

Brief Troubleshooting Guide:

- Poor Cut Quality/Burn Marks: Common issues arise from a dirty protective window, incorrect assist gas pressure/purity, improper focal position (re-check auto-focus calibration), or worn-out nozzles.

- Focus Error Message: Check the power supply to the auto-focus motor, inspect sensor connections, or clean the protective window to ensure clear optical path.

- No Laser Output/Weak Cut: Verify the fiber optic cable connection (ensure it's secure and clean), inspect internal optics for damage/dirt, or check for active safety interlocks.

Brief Installation/Assembly/Dismantling Guide:

Installation typically involves precisely mounting the head onto the machine's Z-axis carriage, securely connecting the fiber optic cable, assist gas lines, electrical cables for control/sensors, and coolant lines. It's a precision assembly task that requires trained personnel to ensure proper optical alignment and system integration. Dismantling is the reverse process, usually performed for maintenance, component replacement, or major overhauls.

Brief Maintenance:

Regular and diligent maintenance is critical for the lifespan and performance of your laser cutting head:

- Protective Window (Cover Slide) Cleaning/Replacement: Routinely inspect and clean/replace this consumable as it acts as the primary shield for internal optics from cutting splatter and fumes.

- Nozzle Inspection: Frequently check for wear, damage, and ensure it is properly centered and aligned with the laser beam.

- Lens Cleaning: Periodically clean internal focusing lenses with optical-grade wipes and specialized solution (this delicate task should only be performed by trained personnel to prevent damage).

- Coolant System Check: Ensure consistent and adequate coolant flow, proper temperature, and regular coolant quality checks to prevent contamination.

(1) Lease Amount per Month:

A. For 3kW Laser Cutting Head (e.g., WSX NC30 Autofocus)

- Lease Amount per month (for 36 months, Ex-GST): INR 5,858/-

B. For 6kW Laser Cutting Head (WSX/Raytools)

- Lease Amount per month (for 36 months, Ex-GST): INR 20,296/-

C. For 12kW Laser Cutting Head (Raytools/Precitec)

- Lease Amount per month (for 36 months, Ex-GST): INR 60,890/-

Why Buy Your FIBERHEAD PRO Online on www.mclease.com?

Don't just buy a component; invest in uninterrupted productivity and complete financial peace of mind!

Acquiring critical parts like a Laser Cutting Head is vital for your operations. While you could buy directly from a supplier, McLease.com offers an unparalleled ecosystem of benefits that no individual component seller or even machine manufacturer can match. We ensure your purchase is not only technologically advanced but also financially smart and fully supported throughout its entire lifecycle.

- Zero Payment to Book! (Only 10% Commitment Fee): Secure your FIBERHEAD PRO today for just 10% of the calculated monthly lease amount as a one-time, refundable order commitment fee. This nominal amount confirms your serious intent, allowing us to prioritize your order. This deposit is 100% refundable if leasing documentation is not proceeded, or if your order is cancelled by McLease. It's truly a risk-free commitment!

- Unmatched 15-Year Service & Spares Assurance: Beyond standard manufacturer warranties, McLease guarantees service and genuine spare parts availability for an incredible 15 years! This commitment ensures your cutting head performs reliably for its entire extended lifespan, minimizing unexpected costs and maximizing uptime.

- Flexible Finance & Easy Leasing: Don't tie up your valuable capital! Opt for our flexible leasing options tailored to your business needs. Our approach often allows approval without rigid CIBIL checks, focusing on your repayment capacity and order book.

- Seamless Online Support Hub: Manage everything from your computer or mobile! Easily purchase all genuine spares, consumables (like protective windows, nozzles), and accessories for your cutting head directly from our intuitive portal. Raise service requests, track engineer movement, and manage your machine's lifecycle digitally.

- AI-Powered Remote Support (RAMC): Minimize costly downtime! Your purchase comes with access to McLease's innovative Remote Annual Maintenance Contracts, offering AI-driven preventive maintenance insights and expert remote troubleshooting, often resolving issues without a site visit.

- Clubbed with Laser Source for Leasing (Additional Reason!): For ultimate convenience and simplified financial management, you can generally club the leasing of your Laser Cutting Head with the entire Laser Source. This means one consolidated lease agreement, streamlined paperwork, and a single point of contact for financing both critical components, making your acquisition process significantly smoother.

- Variety of Payment Modes: Enjoy ultimate flexibility! Pay your initial commitment fee and subsequent monthly lease amounts using Pay Later schemes, Credit/Debit Cards, UPI, Online/Offline Bank Transfers, and even Cash on Delivery (COD) for certain purchases.

- Complete Ecosystem Advantage: By buying from McLease, you gain access to a holistic ecosystem that supports not just this component, but potentially your entire machine fleet, offering comprehensive financing, maintenance, and supply chain solutions.

Why wait? Upgrade your laser cutting performance and secure unparalleled support.

Add the McLease FIBERHEAD PRO to your cart NOW!

Brief Terms & Conditions (Supplementary to Website T&Cs):

- Order Commitment Fee: A one-time non-refundable fee equivalent to 10% of the calculated monthly lease amount is payable to confirm the order.

- Refund Policy: This order commitment fee is 100% refundable if the leasing documentation is not finalized/proceeded, or if the order is cancelled by McLease for any reason. For other cancellation reasons, standard website cancellation policies apply.

- Leasing Approval: Finalization of lease is subject to credit assessment (based on repayment capacity/order book, not CIBIL) and execution of the Lease Agreement.

- Service & Spares Assurance: The 15-year assurance is provided by McLease as per the terms and conditions of a separate Service Assurance Agreement and/or AMC/RAMC contracts.

- Warranty: Manufacturer's standard warranty applies to the product, with McLease facilitating claims.

- GST: All prices and lease amounts are exclusive of GST, which will be charged at the prevailing rates.

0% Advance, No payment to place order.

0% Advance, No payment to place order.

Safe Payment. Escrow & Routing facility.

Safe Payment. Escrow & Routing facility.

Lease and Buy Back / Sell Back.

Lease and Buy Back / Sell Back.

15 year spares, service ASSURED.

15 year spares, service ASSURED.