The McLease LINEMOTION PRO: Precision Ball Screw with Nut is a vital component that translates your machine's motor rotation into incredibly smooth, highly accurate, and efficient linear movement. Think of it as the "precision screw" that precisely moves your CNC machine's cutting head (Z-axis) up and down, ensuring perfect focus and cut depth. Each unit comes as a complete set including the Ball Screw shaft and its matching Ball Nut.

What it is & How it Works (Engineering Principle):

A Ball Screw system consists of a threaded shaft (the ball screw) and a corresponding nut that rides on it. Instead of traditional screw threads, the nut contains recirculating ball bearings that roll in the helical grooves of the shaft. This rolling action (instead of sliding friction) allows for extremely high efficiency, very low friction, and highly precise movement, making it ideal for converting rotary motion from a servo motor into linear motion with minimal backlash (lost motion).

Use & Application:

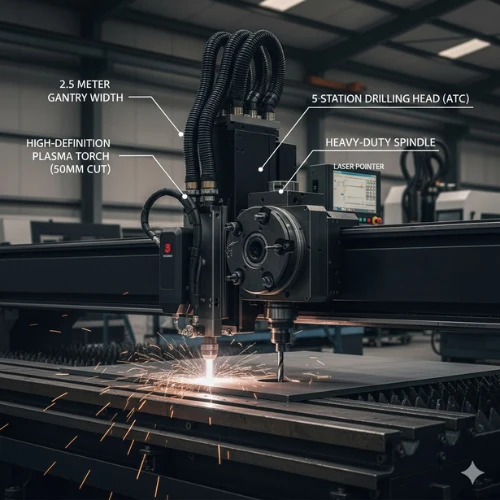

McLease LINEMOTION PRO Ball Screws are critical for the Z-axis (vertical movement) of most CNC metal cutting machines (Fiber Laser, Plasma, OxyFuel). The Z-axis requires exceptional precision for controlling torch height, laser focal point, and piercing operations. They are also used in other demanding linear positioning applications in automation, machine tools, and robotics.

Planning Your Purchase: How Many Ball Screws Do You Need?

For a standard CNC metal cutting machine, typically 1 Ball Screw kit is required for the Z-axis. While the X and Y axes often use linear guide rails and rack & pinion systems for longer travel, the Z-axis, requiring high vertical precision and stiffness, commonly uses a single ball screw for smooth and accurate up-and-down movement of the cutting head.

Choosing Your Ball Screw: Key Specifications (We help you choose!):

- Type of Ball Screw (Affects Precision & Cost):

- Rolled Ball Screws: More common and cost-effective. Suitable for many general industrial CNC applications where very high precision isn't paramount.

- Ground Ball Screws: Offer much higher precision and accuracy (very low backlash). These are often preferred for the Z-axis of Fiber Laser Cutting Machines due to the critical need for precise focus control, but they are more expensive.

- Specifications (Crucial for Z-axis Performance):

- Diameter: Common sizes range from 8mm to 60mm. Larger diameters generally mean higher load capacity, stiffness, and thus higher prices.

- Lead/Pitch: The distance the nut travels per single revolution of the screw (e.g., 5mm, 10mm, 20mm). This affects speed and resolution.

- Length: The total physical length of the ball screw required for your Z-axis travel. Longer screws are more expensive.

- Accuracy Grade (e.g., C7, C5, C3): This defines the precision. C7 is standard for rolled ball screws. C5 and C3 (or even C0 for ultra-precision) indicate much higher precision and are more expensive. For laser and precision CNC, C5 or better is often preferred for the Z-axis.

- Nut Type: Single nut, or double nut (for zero backlash), flange nut, etc. Double nuts are typically used for high-precision applications to eliminate any play.

- Brand:

- Premium Global Brands: THK, HIWIN, PMI, NSK, TBI, Bosch Rexroth, IKO, ABBA are globally recognized for precision and reliability.

- Local Indian/Chinese Brands: Can offer more cost-effective solutions.

Brief Troubleshooting Guide:

- Rough Movement/Sticking: Check for contamination in the nut (dust, chips), lack of lubrication, or mechanical misalignment.

- Excessive Noise: May indicate wear, improper lubrication, or overloading.

- Backlash/Play: Suggests wear on the screw/nut, or issues with support bearings.

Brief Installation & Maintenance Guidelines:

- Installation: Requires careful alignment to prevent bending and ensure smooth operation. The ends of the ball screw typically need specific machining to fit into support bearings (BK/BF, FK/FF) and motor couplings (often purchased separately). This should be done by trained technicians.

- Maintenance: Regular lubrication of the ball nut (via grease nipple) is crucial for longevity and performance. Keep the screw shaft clean from dust and contaminants.

Warranties:

All McLease LINEMOTION PRO Ball Screws come with the standard manufacturer's warranty (typically 12-24 months), covering defects in materials and workmanship.

Outright Sale Prices (No Leasing for this product):

A. Standard Industrial Grade (Rolled Ball Screws)

- Example Model: Rolled Ball Screw with Nut (e.g., TBI/SBC equivalent, C7 accuracy)

- McLease Selling Price: INR 6,000/- per piece

- (Typically for smaller diameters/shorter lengths, or less demanding applications.)

B. Mid-Range Precision (Rolled Ball Screws, Higher Accuracy/Larger Size)

- Example Model: Rolled Ball Screw with Nut (e.g., HIWIN/PMI equivalent, C7/C5 accuracy)

- McLease Selling Price: INR 18,000/- per piece

- (For common CNC Z-axis sizes, offering good precision.)

C. High-Precision (Ground Ball Screws - Recommended for Laser Z-Axis)

- Example Model: Ground Ball Screw with Nut (e.g., THK/Hiwin/PMI equivalent, C5 or C3 accuracy)

- McLease Selling Price: INR 60,000/- per piece

- (Ideal for critical applications like Fiber Laser Z-axes requiring extremely precise focus control.)

(Support units (BK/BF, FK/FF) and motor couplings are typically purchased separately)

Product Attributes (for Ball Screw Selector):

Customers can use / inform these attributes to find the right Ball Screw:

- Type: (e.g., Rolled, Ground)

- Diameter: (e.g., 8mm, 12mm, 16mm, 20mm, 25mm, 32mm, 40mm+)

- Lead/Pitch: (e.g., 5mm, 10mm, 20mm)

- Length (mm): (Customer specifies required length)

- Accuracy Grade: (e.g., C7, C5, C3)

- Nut Type: (e.g., Single Nut, Double Nut, Flange Nut)

- Brand Preference: (e.g., HIWIN, PMI, THK, NSK, TBI, Bosch Rexroth, IKO, ABBA)

- Price Range: (e.g., Below 20k, 20k-50k, Above 50k per piece)

Why Buy Your Precision Ball Screws Online on www.mclease.com?

Achieve Flawless Vertical Precision – Effortlessly!

Precision Ball Screws are critical for your CNC machine's Z-axis, ensuring perfect focus and depth control. While you could buy directly from a supplier, McLease.com offers a curated selection and unique advantages that ensure you get the perfect, high-quality component for unwavering vertical accuracy.

- Precision Matched System: Our Ball Screws come with their precisely matched Ball Nuts, ensuring optimal rolling efficiency and minimal backlash for superior performance.

- Curated & Compatible Selection: We've streamlined your choice! Our LINEMOTION PRO Ball Screws are carefully selected from reputable brands (HIWIN, PMI, THK, NSK, etc.) known for their quality, precision, and compatibility with various CNC machine designs.

- Competitive Pricing: Access high-quality precision motion components at excellent prices, ensuring optimal value for your investment.

- Seamless Online Purchase: Easily browse, compare, and order your Ball Screws from anywhere, anytime, with our user-friendly online platform.

- Manufacturer's Warranty: All LINEMOTION PRO units come with the full manufacturer's warranty, giving you direct assurance from the original maker.

- Expert Guidance (Through Service): While this is an outright sale, our deep understanding of machine components ensures you get the right advice on selection based on your machine's Z-axis load, desired precision, and travel requirements.

- Variety of Payment Modes: Enjoy ultimate flexibility! Pay using Credit/Debit Cards, UPI, Online/Offline Bank Transfers, and even Cash on Delivery (COD) for convenient purchase.

Ensure your machine's vertical movement is flawlessly precise – Upgrade to McLease LINEMOTION PRO today!

Add the McLease LINEMOTION PRO to your cart NOW!

McLease Contact:

Website: shop.mclease.com

Phone: +91-9029026000

Email: info@mclease.com

Precision Ball Screw & Nut - Z-Axis, CNC Laser/Plasma | McLease

Shop McLease LINEMOTION PRO: Precision Ball Screws with Nuts for CNC Z-axis. C5/C3 grade, low backlash. Buy online with manufacturer warranty.

0% Advance, No payment to place order.

0% Advance, No payment to place order.

Safe Payment. Escrow & Routing facility.

Safe Payment. Escrow & Routing facility.

Lease and Buy Back / Sell Back.

Lease and Buy Back / Sell Back.

15 year spares, service ASSURED.

15 year spares, service ASSURED.