Techno-Commercial Proposal:

McLease Nissan Tanaka: CNC Plasma-OxyFuel Metal Plate Profile Cutting Machine

Precision Cutting, High Productivity & Unmatched Support

Prepared for: Valued Client

Date: July 8, 2025

Prepared by: McLease (Vula Technologies Private Limited)

Website: www.mclease.com

Executive Summary

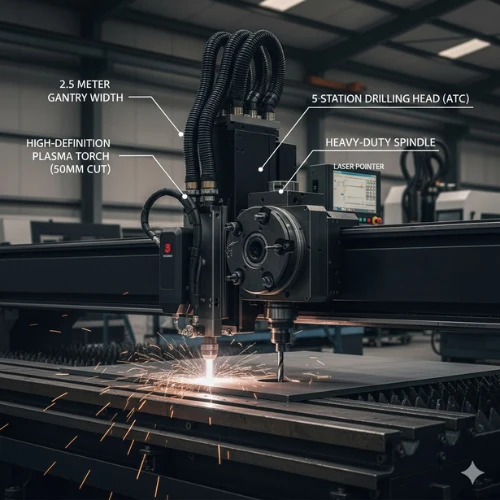

McLease proudly presents the Nissan Tanaka CNC Metal Plate Profile Cutting Machine, a state-of-the-art system exclusively licensed for manufacture in India by McLease through a technical, manufacturing, sales, and service collaboration with its Japanese parent. Designed as a lighter, optimized Indian version for local customers, the Nissan Tanaka machine integrates the most widely available and reliable system components. This robust gantry-type system comes standard with both Plasma and Oxy-Fuel torches, offering unparalleled versatility and efficiency for precision metal cutting. Powered by our reliable HyCut Plasma Power Source (with options for the premium Nissan Tanaka Plasma Power Source or other European brands like Hypertherm), the Nissan Tanaka machine is engineered to deliver high-quality, precise cuts across a wide spectrum of metal types and thicknesses, meeting the demands of modern fabrication.

This proposal details the cutting-edge technology behind the Nissan Tanaka machine, emphasizing its precise motion control, intelligent torch features, and a comprehensive suite of benefits from McLease: flexible financing solutions (including lease with buyback, zero advance options), an industry-leading 15-year service and spares assurance, AI-powered remote maintenance (RAMC), and seamless online support, including hassle-free purchasing of spares, consumables, and accessories on credit/flexible terms. Invest in enhanced productivity, unwavering reliability, and financial peace of mind with McLease Nissan Tanaka.

1. What is a CNC Metal Profile Cutting Machine?

A CNC (Computer Numerical Control) Metal Plate Profile Cutting Machine is an automated system that uses a computer to precisely control the movement of a cutting torch or laser head. Instead of manual guiding, you program the desired shape or "profile" into the computer, and the machine cuts it automatically and accurately from a metal plate.

2. McLease Nissan Tanaka: Machine Specifications

The Nissan Tanaka machine is configured for high-performance and reliable operation, designed for efficient and precise cutting of metal plates.

2.1. Core Machine Components:

2.2. Axes of Motion & Bevel Cutting:

2.3. Intelligent Torch Control Features:

2.4. Cutting Capabilities: Profiles, Metals & Thickness Ranges:

The Nissan Tanaka machine can cut any complex 2D profile.

2.5. How the Machine Defines Its Path & Cuts:

You design parts using CAD software (DXF, DWG), which are then input. Nesting software (like McLease NESTPRO) arranges parts to minimize waste. This layout converts into G-code, which the CNC Controller Unit interprets, sending precise commands to AC Servo Motors. These motors move the gantry and torch(es) along precision linear guides and gear racks & pinions, cutting through metal as guided by the Plasma arc or Oxy-Fuel flame, with Torch Height Control systems ensuring perfect cut quality.

2.6. Nesting Software & Material Savings:

Best nesting software (like McLease NESTPRO) can dramatically save material. Plasma and Oxy-Fuel require a minimum distance between parts due to wider kerf (cut width) compared to laser. While common line cutting is possible, laser generally offers higher material savings due to its finer beam and smaller kerf.

3. Operational Advantages & Benefits

The McLease Nissan Tanaka offers profound operational advantages:

4. Cost Economics: Plasma vs. Oxy-Fuel vs. Laser Cutting

5. Why Buy Your Nissan Tanaka Online on www.mclease.com?

Precision Cutting, Powerful Performance – With Unbeatable Support!

Acquiring a high-performance CNC Plasma-OxyFuel cutting machine is a pivotal investment. While you could buy directly from the manufacturer, McLease.com offers an unparalleled ecosystem of benefits that no individual manufacturer or supplier can match. We ensure your purchase is not only technologically superior but also financially savvy and comprehensively supported throughout its entire lifecycle.

Why choose the HyCut Plasma Power Source with Nissan Tanaka?

For most Indian customers, the HyCut series Plasma Power Source offers the best balance of cost-effectiveness, reliability, and performance. It is specifically chosen for the Indian market to provide robust cutting capabilities without the premium price tag of imported sources. While the Nissan Tanaka Japan-made power source offers premium performance and other international brands like Hypertherm are compatible, the HyCut series ensures you get exceptional cutting quality and high productivity at a significantly lower initial investment and operating cost. This means you achieve your cutting goals faster, with less capital outlay, maximizing your return on investment from day one.

6. Commercial Proposal & Pricing

Variant A: 3-Axis, No Bevel

(e.g., HyCut Power Source, Leadshine servos, TBI linear guides, F2300A controller)

Variant B: 4-Axis with Bevel

(e.g., Nissan Tanaka Power Source / HyCut series, Delta servos, HIWIN linear guides, Friendess controller)

Variant C: Premium: 5-Axis with bevel, Powder Marking

(e.g., Yaskawa/Siemens servos, THK/Rexroth guides, Beckhoff/Fanuc controller for core CNC)

7. Consumables, Spares & Accessories

Maintaining optimal performance requires high-quality consumables and readily available spares. McLease provides easy online access to all your needs:

How to Buy Outright & On Credit/Flexible Pay Terms:

8. Installation Pre-requisites & Customer Responsibilities

Successful installation and optimal performance require careful planning and preparation from the client's side.

8.1. Facility Requirements:

Required Floor Space: Approx. 7-10 meters (Length) x 4-6 meters (Width) clear space.

Height Clearance: Typically 3-4 meters minimum.

8.2. Utilities (To be arranged by Customer):

Electrical Power Supply: Adequate 3-Phase, 415V AC, 50 Hz with breakers and robust earthing (30-80 kVA for up to 300A Plasma).

Industrial Gases: All necessary cutting gases with adequate manifold systems.

Compressed Air Supply: Clean, dry, and regulated (e.g., 7-10 Bar pressure).

Dedicated Earthing Pit: Critically required for safety and stability.

8.3. Site Readiness & Civil Scope:

Machine Foundation: Perfectly level, reinforced concrete foundation as per GA drawing.

Site Preparation: Customer is responsible for preparing the site based on McLease GA layout drawings.

8.4. Material Handling & Support (Customer's Responsibilities):

Unloading & Positioning: Client must arrange tools, tackles, cranes, and forklifts.

Local Assistance: Provide local manpower as required by McLease engineers during installation.

Accommodation: Client is requested to provide decent accommodation (lodging & boarding) for McLease's team.

8.5. Safety:

Site Safety: Client is responsible for ensuring a safe working environment and proper PPE.

Fume Extraction: Client should ensure adequate fume extraction and ventilation systems (McLease offers such systems).

9. How to Buy Your Nissan Tanaka Online on www.mclease.com:

Acquiring your Nissan Tanaka from McLease.com is a streamlined process designed for your convenience:

Step 1: Online Inquiry & Order Booking (Approx. 1-2 Days)

Select Product: Browse www.mclease.com, select "Nissan Tanaka" and your preferred configuration.

Add to Cart & Pay Security Deposit: Add to cart and pay a one-time, 10% refundable Order Booking Security Deposit (as listed in pricing table). Various payment modes available.

Order Confirmation: Receive immediate confirmation and Order ID.

Step 2: Personalized Proposal & Agreement (Approx. 5-7 Days)

Consultation: A McLease expert will contact you within 24-48 hours to confirm final specifications and terms.

Refined Proposal: Receive a precise Techno-Commercial Proposal.

Agreement Finalization: Upon approval, a formal Lease Agreement or Purchase Order will be signed.

Step 3: Machine Manufacturing & Quality Check (Approx. 10-14 Weeks)

Manufacturing: Your Nissan Tanaka will be manufactured by McLease in India under license.

Quality Assurance: Rigorous quality checks performed.

Customer Inspection: You will be invited to inspect the machine at our works before dispatch.

Step 4: Dispatch, Delivery & Final Payment / Lease Commencement (Approx. 1-2 Weeks)

Payment for Outright Purchase: Balance payment due after inspection (as per agreed terms in Section 7).

Lease Commencement: If on lease, tenure officially commences and subscription product is activated for monthly payments.

Dispatch & Transit: Machine dispatched Ex-Factory, Vasai, Mumbai, and delivered to your site.

Step 5: Installation, Commissioning & Training (Approx. 1 Week)

On-site Setup: Our expert engineers will install and commission the machine.

Comprehensive Training: Your nominated personnel will receive thorough training for 4 days.

Go-Live: Your machine is ready for production!

To take the first step towards transforming your fabrication capabilities, click here to add the base model of the Nissan Tanaka CNC Plasma-OxyFuel Metal Plate Profile Cutting Machine with HyCut 125A Plasma, 3000x1500mm bed, to your cart:

Add to Cart: Nissan Tanaka Base Model

10. Brief Terms & Conditions (Supplementary to Website T&Cs):

Prices: All prices are Ex-Works Vasai, Mumbai, India. Indicative estimates, subject to change.

Additional Charges: GST (extra), Freight (actuals, "To Pay"), Packaging, Forwarding, Insurance (PFI: 2% extra).

Installation & Commissioning: Included.

Order Confirmation Deposit: 10% of monthly lease amount, 100% refundable as per refund policy.

Refund Policy: 100% refundable if leasing documentation not finalized or order cancelled by McLease. Other cancellations as per website T&Cs.

Leasing Approval: Subject to McLease's credit assessment and formal Lease Agreement.

Service & Spares Assurance: 15-year assurance as per separate agreement/AMC/RAMC.

Warranty: Manufacturer's standard warranty (12 months from commissioning or 18 months from dispatch, whichever is earlier). McLease facilitates claims.

Machine Ownership (Lease): Legal title remains with McLease's financier or McLease until buy-back.

Governing Law: Laws of India. Courts in Mumbai have exclusive jurisdiction.

McLease Contact:

Website: shop.mclease.com

Phone: +91-9029026000

Email: info@mclease.com

Product Title: McLease Nissan Tanaka: CNC Plasma-OxyFuel Metal Plate Profile Cutting Machine

Product Short Description: Manufactured in India under license from Nissan Tanaka, this robust CNC Plasma-OxyFuel machine offers versatile, precise metal plate cutting. Boost productivity with dual torches, HyCut power, and flexible leasing. Enjoy 15-year service assurance and seamless online support from McLease.

Meta Title: CNC Plasma-OxyFuel Plate Cutting Machine - Nissan Tanaka | McLease India

Meta Description: Shop McLease Nissan Tanaka: Precision CNC Plasma-OxyFuel metal plate cutting machine with dual torches, HyCut power. Flexible leasing & 15-year support in India.

No review given yet!

0% Advance, No payment to place order.

0% Advance, No payment to place order.

Safe Payment. Escrow & Routing facility.

Safe Payment. Escrow & Routing facility.

Lease and Buy Back / Sell Back.

Lease and Buy Back / Sell Back.

15 year spares, service ASSURED.

15 year spares, service ASSURED.