Precision Cutting, High Productivity & Unmatched Support

Prepared for: Valued Client

Date: July 2, 2025

Prepared by: McLease (Vula Technologies Private Limited)

Website:

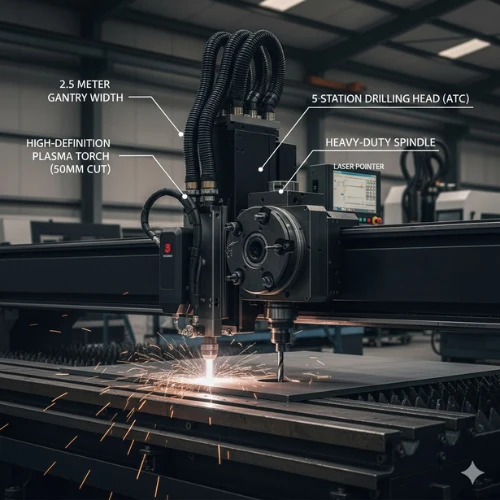

McLease is proud to present the PANTHER PRO, a state-of-the-art CNC Metal Plate Profile Cutting Machine, meticulously manufactured by Technocrats Plasma Systems Ltd., Mumbai, an industry pioneer with over 35 years of expertise. This robust gantry-type system comes standard with both Plasma and Oxy-Fuel torches, offering unparalleled versatility and efficiency for precision metal cutting. Powered by our reliable HyCut Plasma Power Source, the PANTHER PRO is engineered to deliver high-quality, precise cuts across a wide spectrum of metal types and thicknesses, meeting the demands of modern fabrication.

This proposal details the cutting-edge technology behind the PANTHER PRO, emphasizing its precise motion control, intelligent torch features, and a comprehensive suite of benefits from McLease: flexible financing solutions (including lease with buyback, zero advance options), an industry-leading 15-year service and spares assurance, AI-powered remote maintenance (RAMC), and seamless online support, including hassle-free purchasing of spares, consumables, and accessories on credit/flexible terms. Invest in enhanced productivity, unwavering reliability, and financial peace of mind with McLease PANTHER PRO.

A CNC (Computer Numerical Control) Metal Plate Profile Cutting Machine is an automated system that uses a computer to precisely control the movement of a cutting torch or laser head. Instead of manual guiding, you program the desired shape or "profile" into the computer, and the machine cuts it automatically and accurately from a metal plate.

The PANTHER PRO is configured for high-performance and reliable operation, designed for efficient and precise cutting of metal plates.

2.1. Core Machine Components:

Robust Gantry-Type Structure: A sturdy overhead structure that moves along the length of the cutting bed, carrying the cutting torches. Designed for high stability and vibration damping.

Integrated Plasma & Oxy-Fuel Torches: Comes standard with two dedicated torches:

Plasma Torch: For faster cutting of medium to thick metals.

Oxy-Fuel Torch: For cutting very thick mild steel, offering cost-effectiveness.

HyCut Plasma Power Source: Our reliable, high-performance Plasma power source (available in 125A, 200A, 300A options) ensures stable arc and superior cut quality.

Intelligent CNC Control System: The "brain" of the machine that translates digital designs into precise torch movements.

Precision Motion System: High-performance AC Servo Motors, linear guide rails, and gear racks & pinions ensure smooth, accurate motion.

Cutting Bed: An integral part of the machine, where you place your metal sheets. It includes a robust frame and often a water table or downdraft system for fume and slag management.

2.2. Axes of Motion & Bevel Cutting:

Standard (3-Axis) Motion (for Straight Cuts - Entry Range): The machine operates with 3 primary axes for cutting shapes perpendicular to the plate surface:

X-axis: Longitudinal movement of the gantry.

Y-axis: Transverse movement of the cutting torch(es) across the gantry.

Z-axis: Vertical (up-down) movement of the torch for piercing and maintaining correct cutting height.

Advanced (4-Axis) Motion for Bevel Cutting (Mid Range - Includes Bevel as Standard): This configuration adds a rotary axis to the cutting torch, allowing it to tilt for angled cuts.

4th Axis: Typically a rotary axis (e.g., an "A" axis) that allows the torch to tilt to create bevels.

What it does: Enables cutting angled edges (bevels/chamfers) on the metal plate, essential for weld joint preparation.

Premium (5-Axis) Motion for Complex Beveling (Premium Range - Includes Bevel & Complimentary Powder Marking): This top-tier configuration adds even more dexterity to the torch.

5th Axis: Typically another rotary axis (e.g., a "B" axis) that allows the torch to rotate or tilt in a second plane, providing full 360-degree beveling capability for complex joint geometries.

What it does: Allows cutting of highly intricate bevels and weld preparations from multiple directions without repositioning the plate.

2.3. Intelligent Torch Control Features:

Initial Height Sensing (IHS): Automatically senses the plate surface before cutting to determine the correct starting height for the torch.

Arc Voltage Torch Height Control (THC - for Plasma): Continuously monitors the arc voltage during plasma cutting and adjusts the Z-axis (torch height) in real-time to maintain a consistent arc length, ensuring uniform cut quality even on uneven plates.

Capacitive Auto Height Control (for Oxy-Fuel): Uses a sensor to maintain a precise distance between the oxy-fuel torch and the plate surface, crucial for consistent cut quality.

Auto Igniter (for Oxy-Fuel): Automatically ignites the oxy-fuel torch flame, enhancing safety and convenience.

2.4. Cutting Capabilities: Profiles, Metals & Thickness Ranges: The PANTHER PRO can cut any complex 2D profile programmed into its system.

Metals: Primarily Mild Steel (MS), Carbon Steel, Stainless Steel (SS), Aluminum, and Galvanized Plates.

Thickness Ranges (with standard 2 torches):

Plasma Cutting (using HyCut Plasma Source): Excellent for faster cutting of medium to thick metals with good edge quality.

Piercing Capacity: Up to 25-30 mm (Mild Steel).

Edge Cutting Capacity: Up to 35-40 mm (Mild Steel).

Oxy-Fuel Cutting: The most economical method for very thick Mild Steel.

Cutting Capacity: From 5 mm up to 150 mm+ (Mild Steel).

Powder Marking (Complimentary with Premium Range, Optional for others): The machine can also be equipped with a powder marking system (separate attachment) for marking lines, part numbers, or text on the metal surface prior to cutting.

2.5. How the Machine Defines Its Path & Cuts:

Design & Input: You design your parts using CAD software (e.g., DXF, DWG files) and input them into the system. Interfaces include Ethernet (for high-speed data), USB ports (for program transfer via pen drive), and some systems may offer Bluetooth for wireless connectivity.

Nesting: Specialized nesting software (like McLease NESTPRO, available from us) intelligently arranges your parts on a digital sheet of metal to minimize waste.

G-code Generation: The nesting software then converts this layout into machine-readable instructions called G-code, which tells the machine exactly where to move, when to pierce, and when to cut.

Motion Execution: The CNC Controller Unit (the "brain") interprets the G-code and sends precise commands to high-performance AC Servo Motors and drives. These motors move the gantry and torch(es) along precision linear guides and gear racks & pinions, following the exact programmed path.

Cutting: As the torch moves, the Plasma arc or Oxy-Fuel flame cuts through the metal, defining the profile. Torch Height Control systems continuously adjust the vertical position for perfect cut quality.

2.6. Nesting Software & Material Savings: Best nesting software (like McLease NESTPRO) can dramatically save material:

Minimum Distance: Plasma and Oxy-Fuel typically need to keep a minimum distance (kerf width + safety margin) between parts to avoid heat distortion and ensure good cut quality. This is larger than for laser.

Laser Offset vs. Plasma/Oxy-Fuel: Laser cutting has a much finer beam and smaller kerf, allowing parts to be nested much closer, often enabling common line cutting (where parts share an edge), which further reduces material consumption and cutting time. While Plasma/Oxy-Fuel can do common line, the larger kerf makes it less efficient for very tight nests. This is where laser holds an edge in minimizing metal loss.

The McLease PANTHER PRO offers profound operational advantages:

Unmatched Versatility: Standard Plasma and Oxy-Fuel torches handle a vast range of metal thicknesses and types. Optional 4-axis or 5-axis motion enables advanced bevel cutting.

Superior Quality & Accuracy: CNC control, precise motion, and intelligent torch features ensure consistent, high-quality cuts.

Increased Productivity: High cutting speeds and automated processes reduce production time.

Reduced Rework & Material Waste: Precise cuts minimize errors, and optional advanced nesting maximizes material utilization.

Cost-Effective Thick Cutting: Oxy-Fuel provides the most economical solution for very thick mild steel.

Optional Beveling: Reduces/eliminates secondary machining for weld preparation.

Enhanced Safety: Automated operations reduce operator exposure to hazards.

Understanding the economics helps you choose the right tool for the right job:

Precision Cutting, Powerful Performance – With Unbeatable Support!

Acquiring a high-performance CNC Plasma-OxyFuel cutting machine is a pivotal investment. While you could buy directly from the manufacturer, McLease.com offers an unparalleled ecosystem of benefits that no individual manufacturer or supplier can match. We ensure your purchase is not only technologically superior but also financially savvy and comprehensively supported throughout its entire lifecycle.

Manufactured by Technocrats Plasma Systems Ltd., Mumbai: Benefit from over 35 years of engineering excellence from a trusted Indian manufacturer, ensuring robust and reliable machinery with our reliable HyCut Plasma Power Source.

Outright Purchase Advantage (15% Discount): If you choose to buy your PANTHER PRO outright, you receive an exclusive 15% discount on the machine's selling price, offering significant immediate savings.

Zero Payment to Book! (Only 10% Refundable Security Deposit): Secure your PANTHER PRO today for just 10% of the calculated monthly lease amount as a one-time order booking security deposit. This nominal amount confirms your serious intent, allowing us to prioritize your order. This deposit is 100% refundable if leasing documentation is not finalized, or if your order is cancelled by McLease. It's truly a risk-free commitment to explore.

Unmatched 15-Year Service & Spares Assurance: Beyond standard manufacturer warranties, McLease guarantees service and genuine spare parts availability for an incredible 15 years! This commitment ensures your machine performs reliably for its entire extended lifespan, minimizing unexpected costs and maximizing uptime.

Flexible Finance & Easy Leasing with Buyback: Don't tie up your valuable capital! Opt for our flexible leasing options tailored to your business needs, often without rigid CIBIL checks. Our models include buy-back or sell-back options at the end of the lease, giving you ultimate flexibility to upgrade or return.

AI-Powered Remote Support (RAMC) & AMC: Minimize costly downtime! Your machine comes with access to McLease's innovative Remote Annual Maintenance Contracts (RAMC) for AI-driven preventive maintenance insights and expert remote troubleshooting, often resolving issues without a physical visit.

Productivity Loss Insurance: Gain added peace of mind with insurance coverage against productivity loss due to machine breakdowns.

Seamless Online Support Hub: Manage everything from your computer or mobile! Easily purchase all genuine spares, consumables (like plasma electrodes, nozzles, oxy-fuel tips, cutting gases), and accessories directly from McLease.com. Raise service requests, track engineer movement, and manage your machine's lifecycle digitally.

Variety of Payment Modes: Enjoy ultimate flexibility! Pay your initial security deposit and subsequent monthly lease amounts using Pay Later schemes, Credit/Debit Cards, UPI, Online/Offline Bank Transfers, and even Cash on Dispatch (COD) for the machine itself (terms apply).

Complete Ecosystem Advantage: By choosing McLease, you gain access to a holistic ecosystem that supports not just this machine, but potentially your entire fabrication operation, offering comprehensive financing, maintenance, and supply chain solutions.

Optional Bundling of Essential Accessories: For complete peace of mind and simplified procurement, you can bundle essential ancillary systems like Fume Extraction Systems/Dust Collectors, Air Compressor & Air Dryer Units, and Power Conditioning Units (Online UPS / Voltage Stabilizer / Isolation Transformer) directly with your machine order, ensuring optimal machine health and operator safety from day one.

All prices are indicative and subject to final configuration, prevailing market conditions, and GST (Goods and Services Tax) as applicable. The prices below are for monthly lease for 3 year term. If you want to buy on outright purchase basis, request you to still book the machine and later opt for outright during lease documentation meeting. Will be happy to pass on 15% discount in addition to other discounts as per machine configuration.

Variant A: Entry Range (3-Axis, No Bevel - Cost-Effective Components - e.g., Leadshine servos, TBI linear guides, F2300A controller)

Variant B: Mid-Range (4-Axis, INCLUDES Bevel - Reputable Chinese/Taiwanese Components - e.g., Delta servos, HIWIN linear guides, Friendess controller)

Variant C: Premium Range (5-Axis, INCLUDES Complimentary Powder Marking - Global Brands - e.g., Yaskawa/Siemens servos, THK/Rexroth guides, Beckhoff/Fanuc controller for core CNC)

Maintaining optimal performance requires high-quality consumables and readily available spares. McLease provides easy online access to all your needs:

Plasma Consumables: Electrodes, Nozzles, Swirl Rings, Shield Caps, Retaining Caps, Ceramic Shields.

Oxy-Fuel Consumables: Cutting Nozzles (Tips), Heating Nozzles.

Welding Gases: Oxygen (for Plasma/Oxy-Fuel), Fuel Gas (Acetylene/Propane for Oxy-Fuel), Compressed Air/Nitrogen (for Plasma assist). (McLease offers Gas Regulators & Hoses).

General Machine Spares: Linear Guide Blocks/Rails, Pinions, Gearboxes, Servo Motors/Drives, Ball Screws (for Z-axis), CNC Controller Units, Welding Cables, Fuses, Sensors, Limit Switches, Relays.

Accessories: Nesting Software Licenses, CAD/CAM Software Licenses, Fume Extraction Systems/Filters, Air Compressor & Dryer Units, Water Chiller Units, Power Conditioning Units (UPS, Stabilizer, Transformer).

How to Buy Outright & On Credit/Flexible Pay Terms:

Outright Purchase (for the machine):

Option A: 50% Advance with Bank Guarantee: Pay 50% advance (McLease provides BG for non-delivery), remaining 50% against dispatch.

Option B: Zero Advance with 100% Customer Bank Guarantee: Provide 100% BG, pay 100% against dispatch.

Buying Spares, Consumables & Accessories on Credit / Flexible Pay Terms:

For our corporate customers, McLease offers a unique facility to "top-up your digital wallet" with a credit limit of up to INR 5 Lakh.

You can instantly consume this credit limit by purchasing spares, consumables, and accessories directly from the McLease.com portal or mobile app.

You do not have to pay immediately! This amount can be repaid in a monthly billing cycle or as per a mutually agreed credit limit and credit period. This significantly streamlines your procurement and cash flow for recurring operational needs.

Successful installation and optimal performance require careful planning and preparation from the client's side.

8.1. Facility Requirements:

Required Floor Space: For a standard PANTHER PRO (e.g., 3000x1500mm to 6000x2500mm beds), you will need clear floor space of approx. 7-10 meters (Length) x 4-6 meters (Width), including space for machine travel, material handling, and access.

Height Clearance: Sufficient overhead clearance for the gantry and torch movement (typically 3-4 meters minimum).

8.2. Utilities (To be arranged by Customer):

Electrical Power Supply: Adequate 3-Phase, 415V AC, 50 Hz power supply with appropriate main circuit breakers and robust earthing. For configurations up to 300A Plasma, a connected load capacity of 30-80 kVA is typically required.

Industrial Gases: Availability of all necessary cutting gases (Oxygen, Fuel Gas for Oxy-Fuel; Compressed Air/Oxygen/Nitrogen for Plasma) at the cutting table, with adequate manifold systems, cylinders or pipeline connections, and proper regulators (McLease offers regulators & hoses).

Compressed Air Supply: Clean, dry, and regulated compressed air supply (e.g., 7-10 Bar pressure) for plasma cutting and pneumatic controls (McLease offers Air Compressor & Air Dryer Units).

Dedicated Earthing Pit: A separate, dedicated industrial earthing pit or a robust industrial earthing system is critically required for the machine and its control panels. This ensures electrical safety for personnel and stability for sensitive electronic components.

8.3. Site Readiness & Civil Scope:

Machine Foundation: A perfectly level, reinforced concrete foundation (thickness and reinforcement as per our General Arrangement (GA) layout drawing) is crucial for machine stability and accuracy.

Site Preparation: Customer is responsible for preparing the site based on the General Arrangement (GA) layout drawings provided by McLease.

8.4. Material Handling & Support (Customer's Responsibilities):

Unloading & Positioning: Client must arrange and provide necessary tools, tackles, cranes, and forklifts for unloading and positioning machine components.

Local Assistance: Provide local manpower (electricians, fitters, laborers) as required by McLease engineers during installation.

Accommodation: Client is requested to provide decent accommodation (lodging & boarding) for McLease's team.

8.5. Safety:

Site Safety: Client is responsible for ensuring a safe working environment and proper PPE for all personnel.

Fume Extraction: Client should ensure adequate fume extraction and ventilation systems are in place (McLease offers such systems) for a healthy work environment during operation.

Acquiring your PANTHER PRO from McLease.com is a streamlined process designed for your convenience:

Step 1: Online Inquiry & Order Booking (Approx. 1-2 Days)

Select Product: Browse

Add to Cart & Pay Security Deposit: Add the product to your cart. To confirm your serious intent and secure your order, you will pay a one-time, 10% refundable Order Booking Security Deposit (as listed next to monthly lease amount in pricing table). This deposit can be paid using various modes including Credit/Debit Cards, UPI, Online Bank Transfer (NEFT/RTGS), Wallets, Pay Later options, and even Cash on Dispatch (COD) for the final machine payment (terms apply).

Order Confirmation: You will receive an immediate confirmation and Order ID.

Step 2: Personalized Proposal & Agreement (Approx. 5-7 Days)

Consultation: A McLease expert will contact you within 24-48 hours of order booking. We will confirm final machine specifications, power needs, site conditions, and desired payment/lease terms.

Refined Proposal: Based on your inputs, we will prepare a precise Techno-Commercial Proposal.

Agreement Finalization: Upon your approval, a formal Lease Agreement or Purchase Order will be signed.

Step 3: Machine Manufacturing & Quality Check (Approx. 10-14 Weeks)

Manufacturing: Your PANTHER PRO will be manufactured by Technocrats Plasma Systems Ltd.

Quality Assurance: Rigorous quality checks are performed at various stages.

Customer Inspection: You will be invited to inspect the machine at our works before dispatch.

Step 4: Dispatch, Delivery & Final Payment / Lease Commencement (Approx. 1-2 Weeks)

Payment for Outright Purchase: If purchased outright, the balance payment is due after inspection (as per agreed terms in Section 7).

Lease Commencement: If on lease, the lease tenure officially commences, and the subscription product is activated in your online cart for monthly payments.

Dispatch & Transit: Machine is dispatched Ex-Factory, Vasai, Mumbai, and delivered to your site.

Step 5: Installation, Commissioning & Training (Approx. 1 Week)

On-site Setup: Our expert engineers will install and commission the PANTHER PRO at your facility.

Comprehensive Training: Your nominated personnel will receive thorough training on machine operation, multi-torch switching, basic maintenance, and software utilization for 4 days.

Go-Live: Your machine is ready for production!

Prices: All prices are Ex-Works Vasai, Mumbai, India. Prices are indicative estimates and subject to change based on final technical specifications and market conditions.

Additional Charges:

GST: Goods and Services Tax will be extra, as applicable, on all machine values, payments, and services.

Freight: Transportation charges will be at actuals and "To Pay" (customer pays directly at delivery).

Packaging, Forwarding, Insurance (PFI): A charge of 2% of the machine value will be extra.

Installation & Commissioning: Included in the price.

Order Confirmation Deposit: A one-time refundable security deposit (10% of monthly lease amount) is required at the time of online order booking. This deposit is 100% refundable as per the refund policy stated.

Refund Policy: This order confirmation fee is 100% refundable if the leasing documentation is not finalized/proceeded, or if the order is cancelled by McLease for any reason. For other cancellation reasons, standard website cancellation policies (

Leasing Approval: Finalization of lease is subject to McLease's credit assessment (based on repayment capacity/order back) and execution of a formal Lease Agreement.

Service & Spares Assurance: The 15-year assurance is provided by McLease as per the terms and conditions of a separate Service Assurance Agreement and/or AMC/RAMC contracts.

Warranty: The machine comes with a manufacturer's standard warranty, typically 12 months from the date of commissioning or 18 months from the date of dispatch, whichever is earlier. McLease facilitates warranty claims.

Machine Ownership (Lease): Legal title of the machine under a lease arrangement remains with McLease's financier or McLease, as specified in the Lease Agreement, until buy-back option is exercised.

Governing Law: This proposal and any resulting agreements shall be governed by the laws of India. Courts in Mumbai shall have exclusive jurisdiction.

McLease Contact: Website: shop.mclease.com Phone: +91-9029026000 Email: info@mclease.com

No review given yet!

0% Advance, No payment to place order.

0% Advance, No payment to place order.

Safe Payment. Escrow & Routing facility.

Safe Payment. Escrow & Routing facility.

Lease and Buy Back / Sell Back.

Lease and Buy Back / Sell Back.

15 year spares, service ASSURED.

15 year spares, service ASSURED.