Precision Pipe Cutting, High Productivity & Unmatched Support

Prepared for: Valued Client

Date: July 2, 2025

Prepared by: McLease (Vula Technologies Private Limited)

Website: www.mclease.com

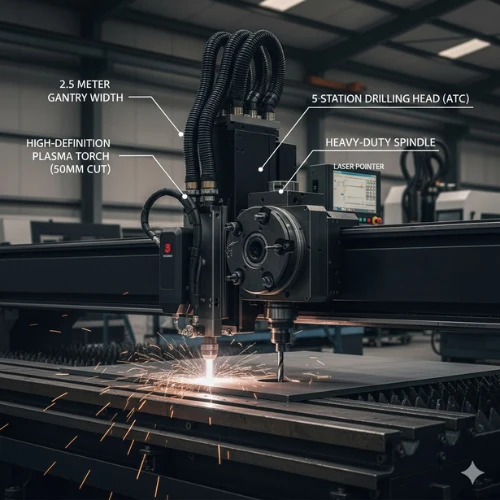

McLease presents the PUMA PRO, a state-of-the-art CNC Pipe Profile Cutting Machine, meticulously manufactured by Technocrats Plasma Systems Ltd., Mumbai, an industry pioneer with over 35 years of expertise. This robust system comes standard with both Plasma and Oxy-Fuel torches, offering unparalleled versatility and efficiency for precision pipe cutting. Powered by our reliable HyCut Plasma Power Source, the PUMA PRO is engineered to deliver high-quality, precise cuts across a wide spectrum of metal types, thicknesses, and complex shapes for pipes, meeting the demands of modern fabrication.

This proposal details the cutting-edge technology behind the PUMA PRO, emphasizing its precise motion control, intelligent torch features, and a comprehensive suite of benefits from McLease: flexible financing solutions (including lease with buyback), 15-year service and spares assurance, AI-powered remote maintenance (RAMC), and seamless online support, including hassle-free purchasing of spares, consumables, and accessories on credit/flexible terms. Invest in enhanced productivity, unwavering reliability, and financial peace of mind with McLease PUMA PRO.

A CNC (Computer Numerical Control) Pipe Profile Cutting Machine is an automated system that uses a computer to precisely control the movement of a cutting torch as it moves around and along a cylindrical pipe. You program the desired shapes (profiles) into the computer, and the machine precisely controls the cutting torches to automatically cut various contours, holes, and end preparations onto the pipe surface.

The PUMA PRO is configured for high-performance and reliable operation for pipe cutting.

2.1. Core Machine Components:

Robust Gantry-Type Structure: A sturdy overhead structure that moves along the length of the machine's base, carrying the cutting torches. Designed for high stability and vibration damping.

Integrated Plasma & Oxy-Fuel Torches: Standard dual torches for versatile cutting of medium-to-thick metals (Plasma) and very thick mild steel (Oxy-Fuel) on pipes.

HyCut Plasma Power Source: Our reliable, high-performance Plasma power source (available in 125A, 200A, 300A options) ensures stable arc and superior cut quality.

Intelligent CNC Control System: The machine's "brain" that translates digital designs into precise torch movements for pipe cutting.

Precision Motion System: High-performance AC Servo Motors, linear guide rails, and gear racks & pinions ensure smooth, accurate motion.

Pipe Cutting Section: A dedicated, integrated section for pipes. Choose between robust chuck-based systems (for firm gripping and precise rotation of pipes) or roller-disc based systems (for versatile pipe support and rotation) as per your operational requirements.

2.2. Axes of Motion & Bevel Cutting:

Standard (3-Axis) Motion (Entry Range): The machine operates with 3 primary axes for cutting shapes perpendicular to the pipe surface:

X-axis: Longitudinal movement of the gantry along the pipe length.

Y-axis: Transverse movement of the cutting torch(es) across the gantry.

Z-axis: Vertical (up-down) movement of the torch for piercing and maintaining correct cutting height.

(Note: The pipe's rotation itself acts as a synchronized axis for cutting the profile around its circumference.)

Advanced (4-Axis) Motion for Bevel Cutting (Mid Range - Includes Bevel as Standard): This configuration adds a rotary axis to the cutting torch, allowing it to tilt for angled cuts on pipes.

4th Axis: Typically a rotary axis (e.g., an "A" axis) that allows the torch to tilt to create bevels (chamfers), essential for weld joint preparation.

Premium (5-Axis) Motion for Complex Beveling (Premium Range - Includes Bevel & Complimentary Powder Marking): This top-tier configuration adds even more dexterity to the torch for pipe cutting.

5th Axis: Typically another rotary axis (e.g., a "B" axis) that allows the torch to rotate or tilt in a second plane, providing full 360-degree beveling capability for complex joint geometries on pipes.

2.3. Intelligent Torch Control Features:

Initial Height Sensing (IHS): Auto-senses the pipe surface before cutting to determine the correct starting height for the torch.

Arc Voltage Torch Height Control (THC - for Plasma): Continuously monitors the arc voltage during plasma cutting and adjusts the Z-axis (torch height) in real-time to maintain a consistent arc length on uneven/oval pipes.

Capacitive Auto Height Control (for Oxy-Fuel): Maintains precise torch distance from the pipe surface.

Auto Igniter (for Oxy-Fuel): Automatically ignites the torch for safety and convenience.

2.4. Cutting Capabilities: Profiles, Metals & Thickness Ranges:

The PUMA PRO can cut various profiles from pipes.

Metals (for Pipe): Primarily Mild Steel (MS), Carbon Steel, Stainless Steel (SS), Aluminum, and Galvanized Pipes.

Pipe Cutting Specifications:

Pipe Length Range: Minimum 750 mm to Maximum 6000 mm and beyond (customizable).

Pipe Diameter Range: Minimum 60 mm to Maximum 500 mm (customizable).

Pipe Wall Thickness Range: Typically 4 mm to 14 mm (can vary based on power source).

Pipe Profiles: Capable of cutting various pipe profiles, including straight cuts, holes, slots, saddle cuts, miters, branch connections, and other complex contours, all precisely controlled.

Powder Marking (Complimentary with Premium Range, Optional for others): The machine can be equipped with a powder marking system (separate attachment) for marking lines, part numbers, or text on the metal surface (pipe surface) prior to cutting.

2.5. How the Machine Defines Its Path & Cuts:

Design & Input: You design your pipe parts using CAD software (e.g., DXF, DWG files). Specialized pipe unfolding software is used to convert 3D pipe designs into flat cutting paths that are then transferred to the pipe surface. Interfaces include Ethernet (for high-speed data), USB ports (for program transfer), and some systems may offer Bluetooth.

Nesting: Specialized nesting software (like McLease NESTPRO) intelligently arranges parts on the digital pipe surface to minimize waste.

G-code Generation: The nesting/pipe unfolding software converts layouts into machine instructions (G-code).

Motion Execution: The CNC Controller Unit (the "brain") commands high-performance AC Servo Motors and drives to move the gantry and torch(es) along precision linear guides and gear racks & pinions, or precisely rotate the pipe via the chuck/roller system, following the exact programmed path.

Cutting: As the torch moves and the pipe rotates, the Plasma arc or Oxy-Fuel flame cuts through the metal, guided by precise motion and continuous height control.

2.6. Nesting Software & Material Savings:

Best nesting software (like McLease NESTPRO) can dramatically save material by optimizing layouts for pipes, significantly reducing raw material waste.

The McLease PUMA PRO offers profound operational advantages:

Specialized Pipe Cutting: Designed specifically for accurate and efficient cutting of cylindrical pipes.

Superior Quality & Accuracy: CNC control, precise motion, and intelligent torch features ensure consistent, high-quality cuts on pipes.

Increased Productivity: High cutting speeds and automated processes reduce production time for pipe fabrication.

Reduced Rework & Material Waste: Precise cuts minimize errors, and advanced pipe unfolding maximizes material utilization.

Cost-Effective Thick Cutting: Oxy-Fuel provides an economical solution for very thick mild steel pipes.

Optional Beveling: Reduces/eliminates secondary machining for weld preparation on pipes.

Enhanced Safety: Automated operations reduce operator exposure to hazards.

Precision Pipe Cutting, Powerful Performance – With Unbeatable Support!

Acquiring a high-performance CNC Plasma-OxyFuel Pipe cutting machine is a pivotal investment. While you could buy directly from the manufacturer, McLease.com offers an unparalleled ecosystem of benefits that no individual manufacturer or supplier can match. We ensure your purchase is not only technologically superior but also financially savvy and comprehensively supported throughout its entire lifecycle.

Manufactured by Technocrats Plasma Systems Ltd., Mumbai: Benefit from over 35 years of engineering excellence from a trusted Indian manufacturer, ensuring robust and reliable machinery with our reliable HyCut Plasma Power Source.

Outright Purchase Advantage (15% Discount): If you choose to buy your PUMA PRO outright, you receive an exclusive 15% discount on the machine's selling price, offering significant immediate savings.

Zero Payment to Book! (Only 10% Refundable Security Deposit): Secure your PUMA PRO today for just 10% of the calculated monthly lease amount as a one-time order booking security deposit. This nominal amount confirms your serious intent, allowing us to prioritize your order. This deposit is 100% refundable if leasing documentation is not finalized, or if your order is cancelled by McLease. It's truly a risk-free commitment to explore.

Unmatched 15-Year Service & Spares Assurance: Beyond standard manufacturer warranties, McLease guarantees service and genuine spare parts availability for an incredible 15 years! This commitment ensures your machine performs reliably for its entire extended lifespan, minimizing unexpected costs and maximizing uptime.

No review given yet!

0% Advance, No payment to place order.

0% Advance, No payment to place order.

Safe Payment. Escrow & Routing facility.

Safe Payment. Escrow & Routing facility.

Lease and Buy Back / Sell Back.

Lease and Buy Back / Sell Back.

15 year spares, service ASSURED.

15 year spares, service ASSURED.